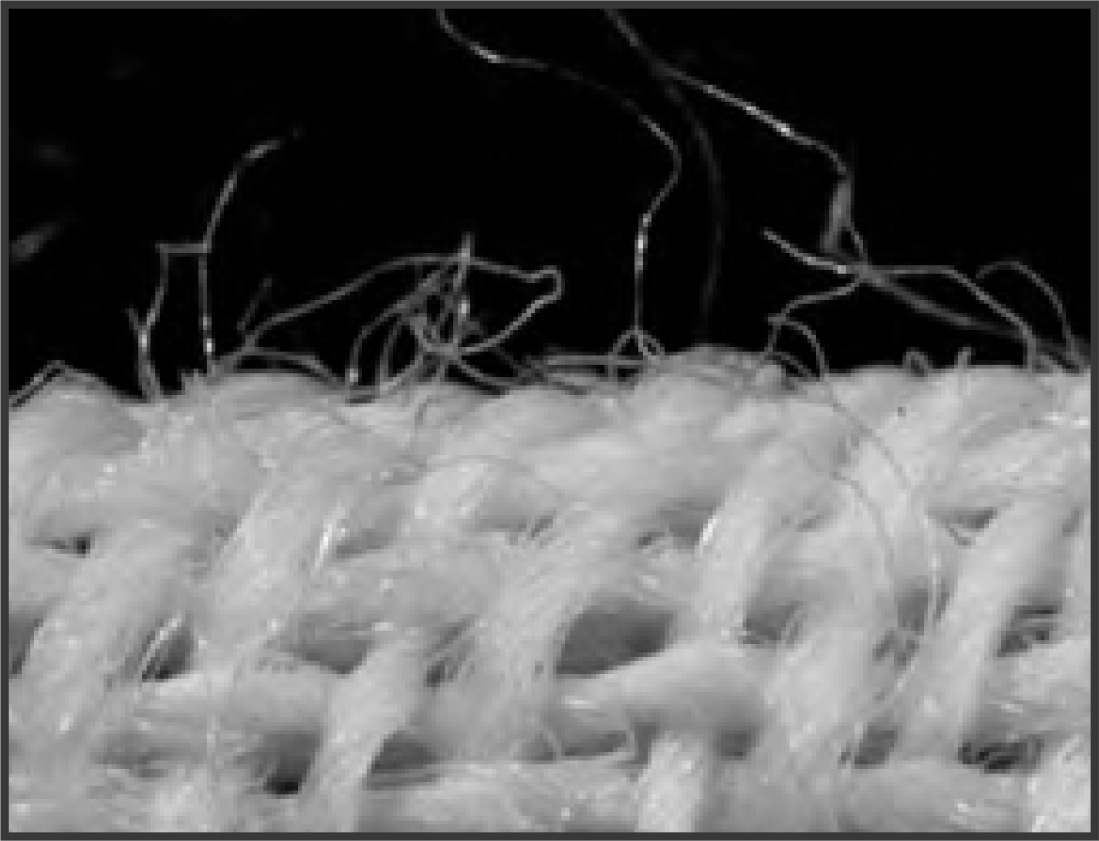

The loose projected fibers do swell during the mercerization and the swelling prohibits penetration of caustic liquor in the fabric as loose fibers due to poor singeing swells and mask the entry of caustic inside the fabric.

In the case of ‘FOURWENTS’ singeing this is additional feature being offered through the effective and clean singeing.

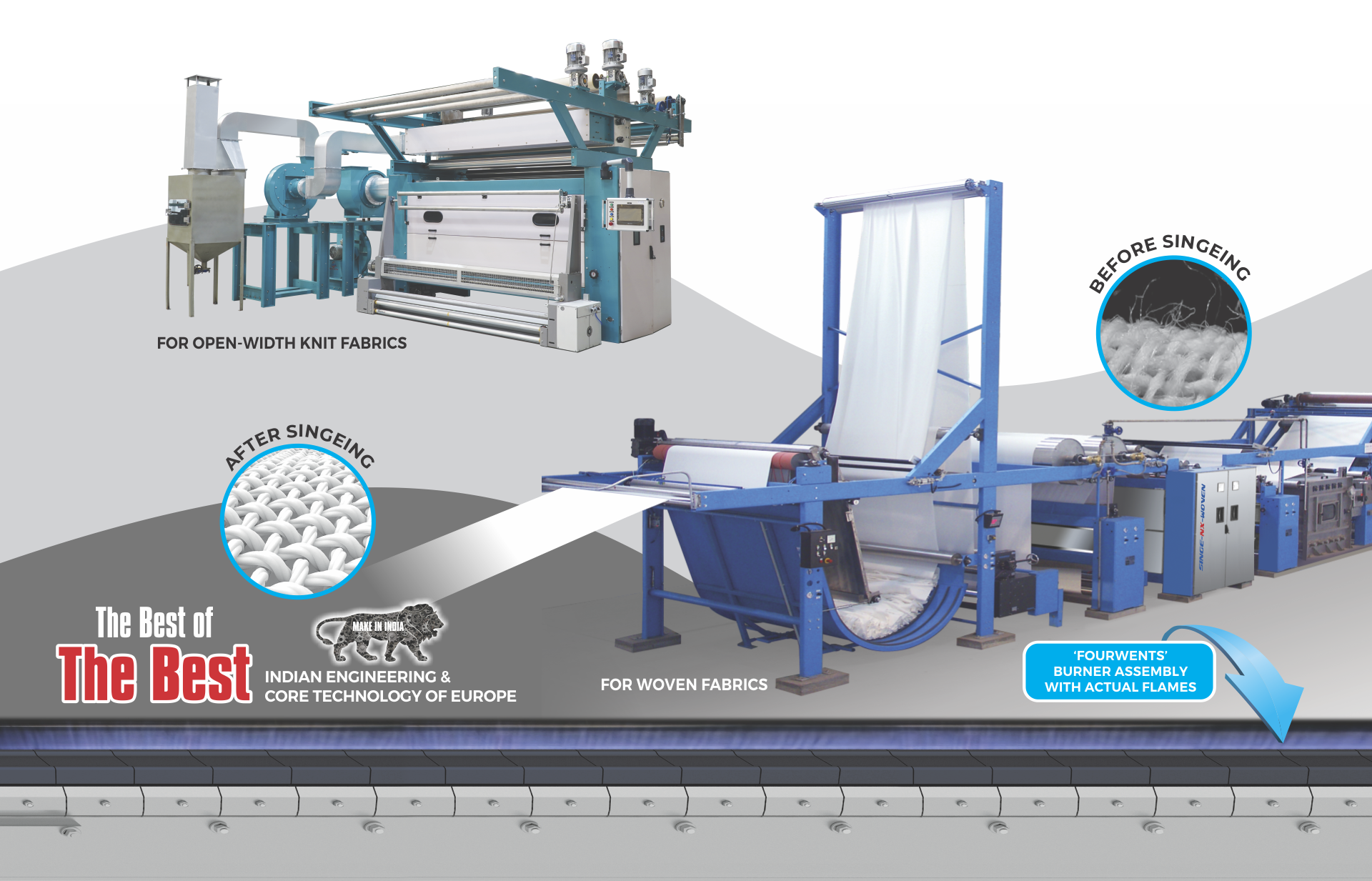

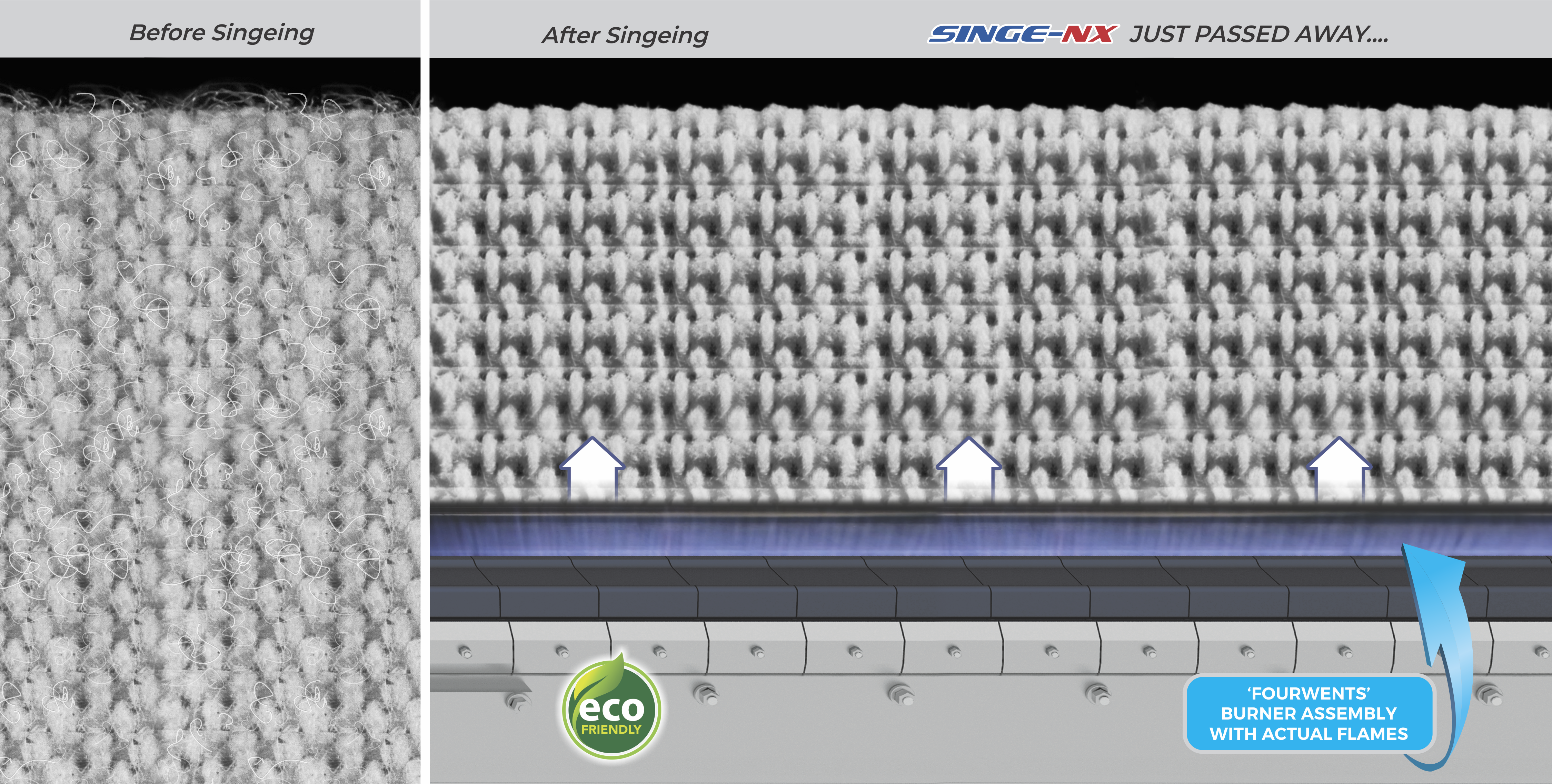

Singeing of woven and knitted fabric plays a significant part in fabric pretreatment, appearance, clean and clear surface prior to the fabric's subsequent process. Singeing of woven and knitted fabric is done to eliminate and burn off the hairiness on the cloth surface and give a smooth surface finish.

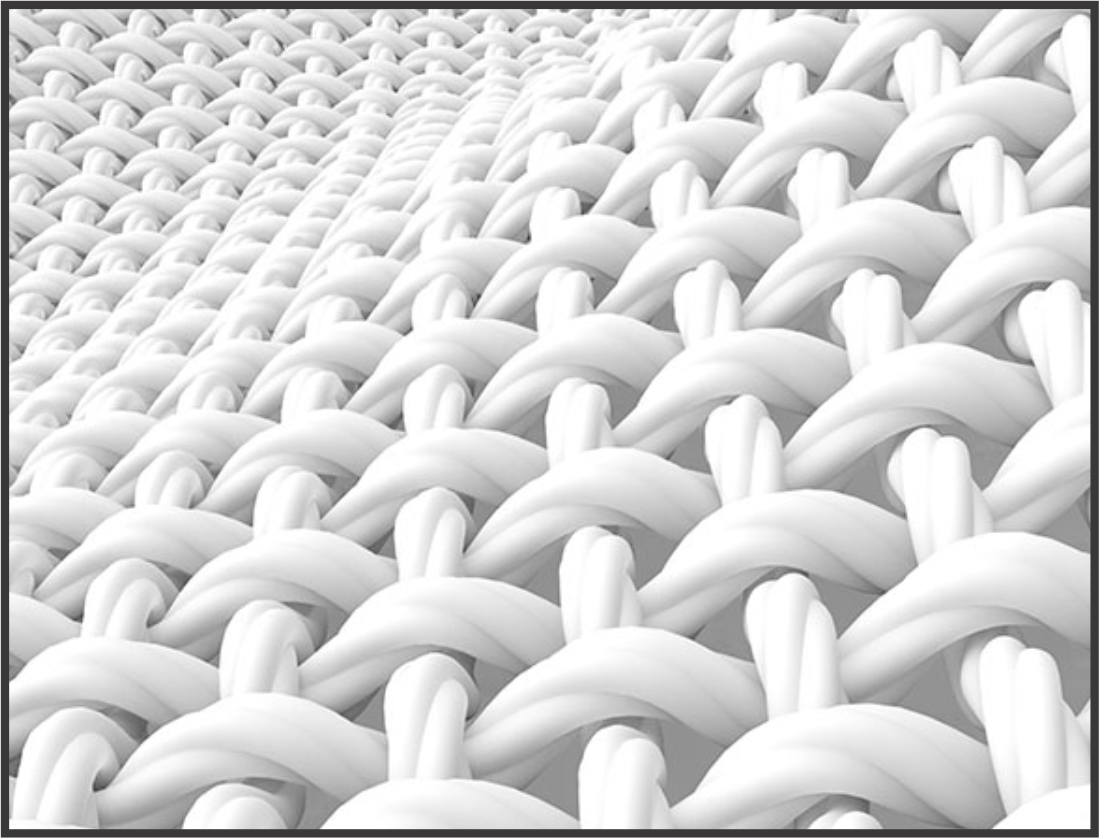

The process guarantees several purposes like to obtain a clean surface which allows the structure of the fabric to be clearly seen, reduced risk of pilling, better printing of fine designs with an higher clarity and details, less risks of irregular dyeing process especially in dark shades due to diffused reflection of light.

?

?In terms of hairiness removal, the SINGE-NX singeing method can ensure the highest quality standards. The consistency of the flame across the entire width of the burners enables the finest possible results.

The ability to set the burners tangentially or perpendicularly allows you to run a wide range of objects from the most delicate to the heaviest. The machine's production and controls are fully automated, with supervision of all production data required for machine setup.

The singeing line can also be supplied with a desizing process with the main goal of obtaining a fabric free of sizes so that the penetration of dyeing, printing, and finishing chemicals results in the highest possible quality of your products.

Myth of singeing as a preliminary process exists in the industries as the full width fabric passes rapidly through a flame issuing form a width long gas burner. This burn of the producing fibres ends projecting from the fabric surface without any damage to the fabric. The result is the plain clean surface look.

We look singeing from different angle and study all micro elements for burning exposed fibers either short or long created from the abrasion of the yarn during high speed weaving. The result is smoother and clean and effective look. Final finish fabric is having sheen due to this clean surface.

Four ways of getting benefit from ‘Fourwents’ singeing unless the fiber is uniform in surface, it is unlikely that it will appear smooth and round. Singeing is the first stage in wet processing sequence where it imparts to the fabric.

Fourwents singer does not chemically modify the cellulose. Neither the singeing has any other impact on its tensile and tear strength.

The peripheral surface burning of projected hairs brings beautification by improved appearance later.

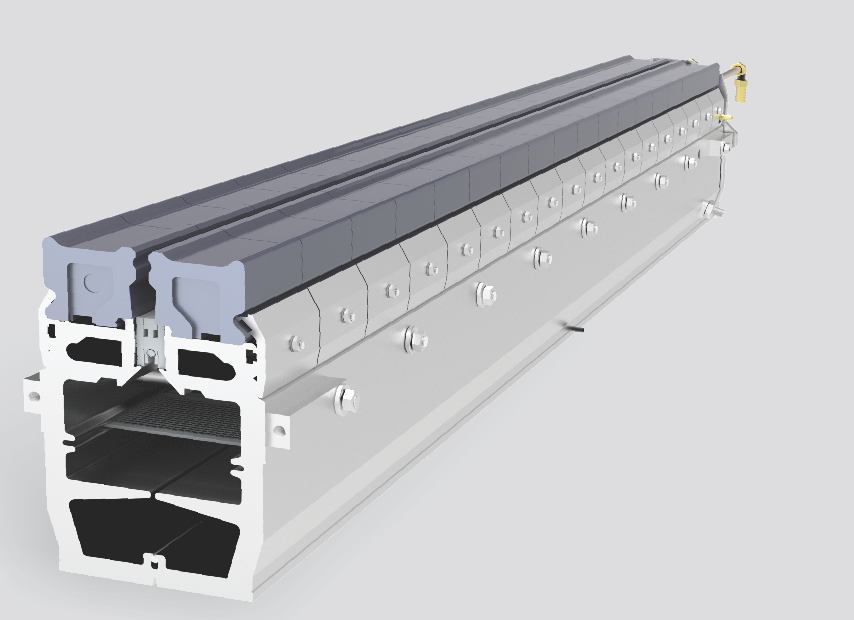

WORLD CLASS DUAL-JET GAS BURNER

SINGEING MACHINE, BRUSHING & BEATER UNIT

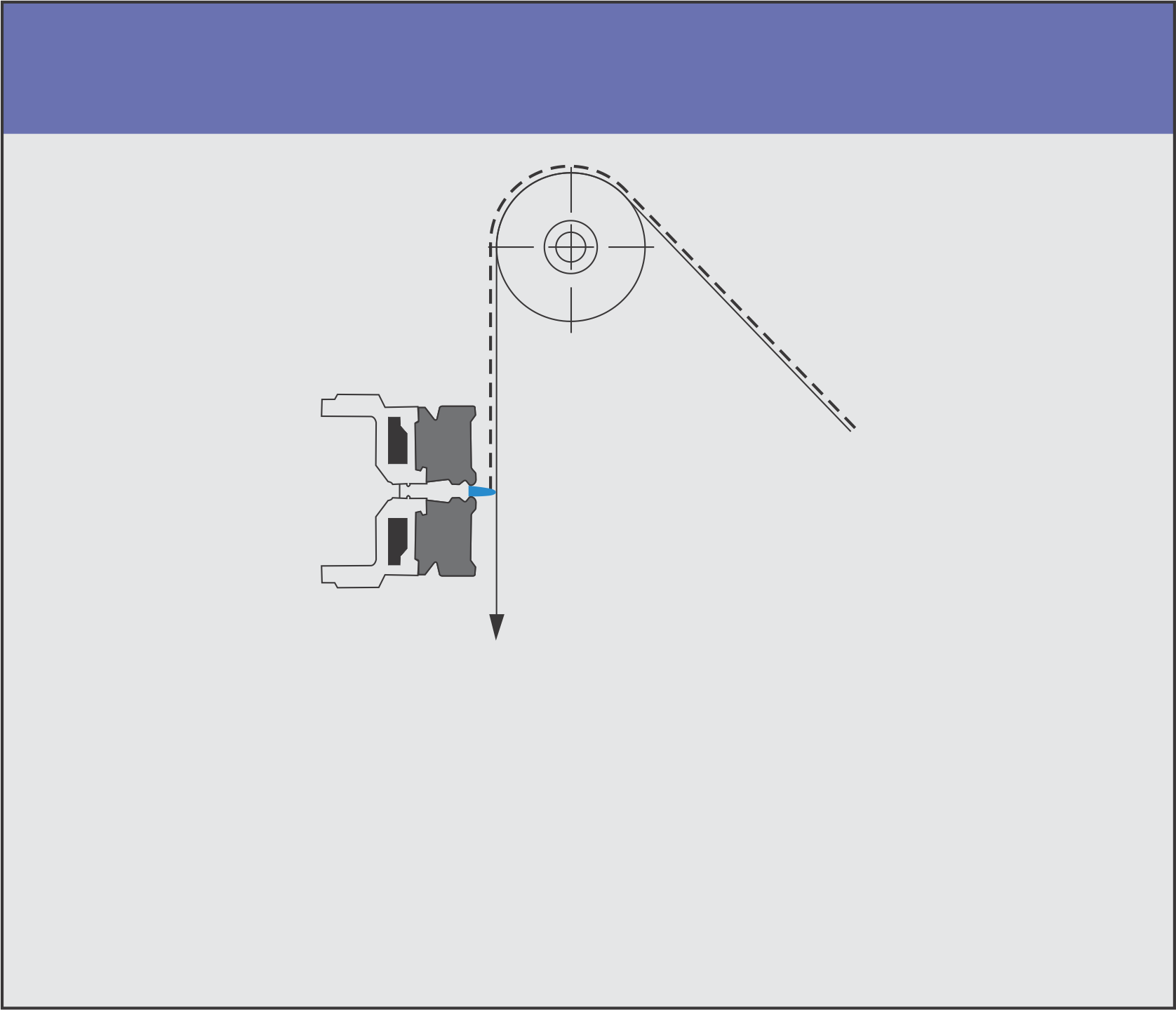

The singeing flame meets the free guided fabric at right angles as the fabric passes between two guide rollers. The position is suitable for 100% natural fibers and for blended fabrics which have been thoroughly beaten, with weights over 125g/m².

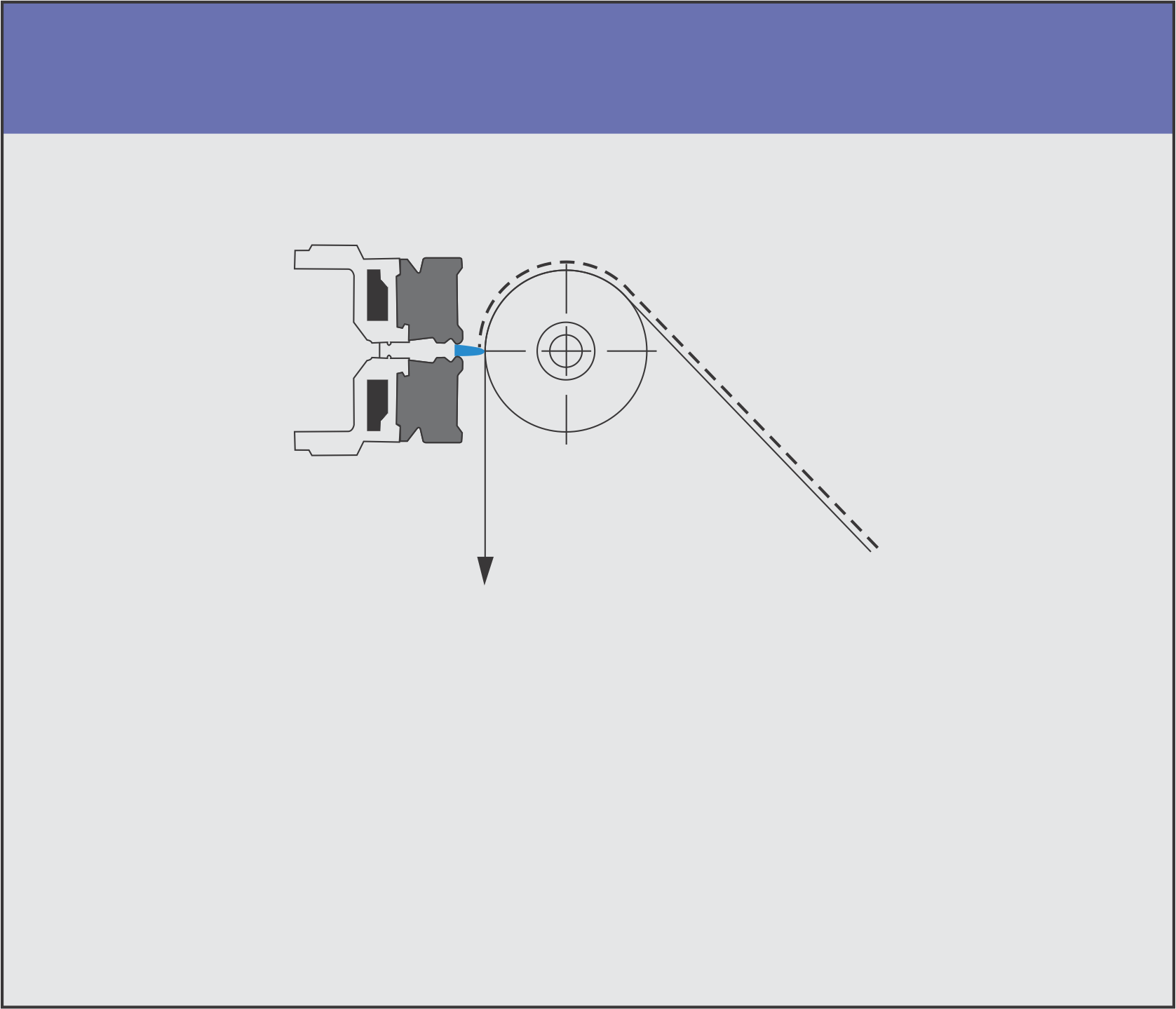

The singeing flame meets at right angle on to the fabric passing over a water cooled roller. This option normally for quality composed of temperature sensitive fibers, open-weave blended fabrics and those with weights of less than 125g/m².

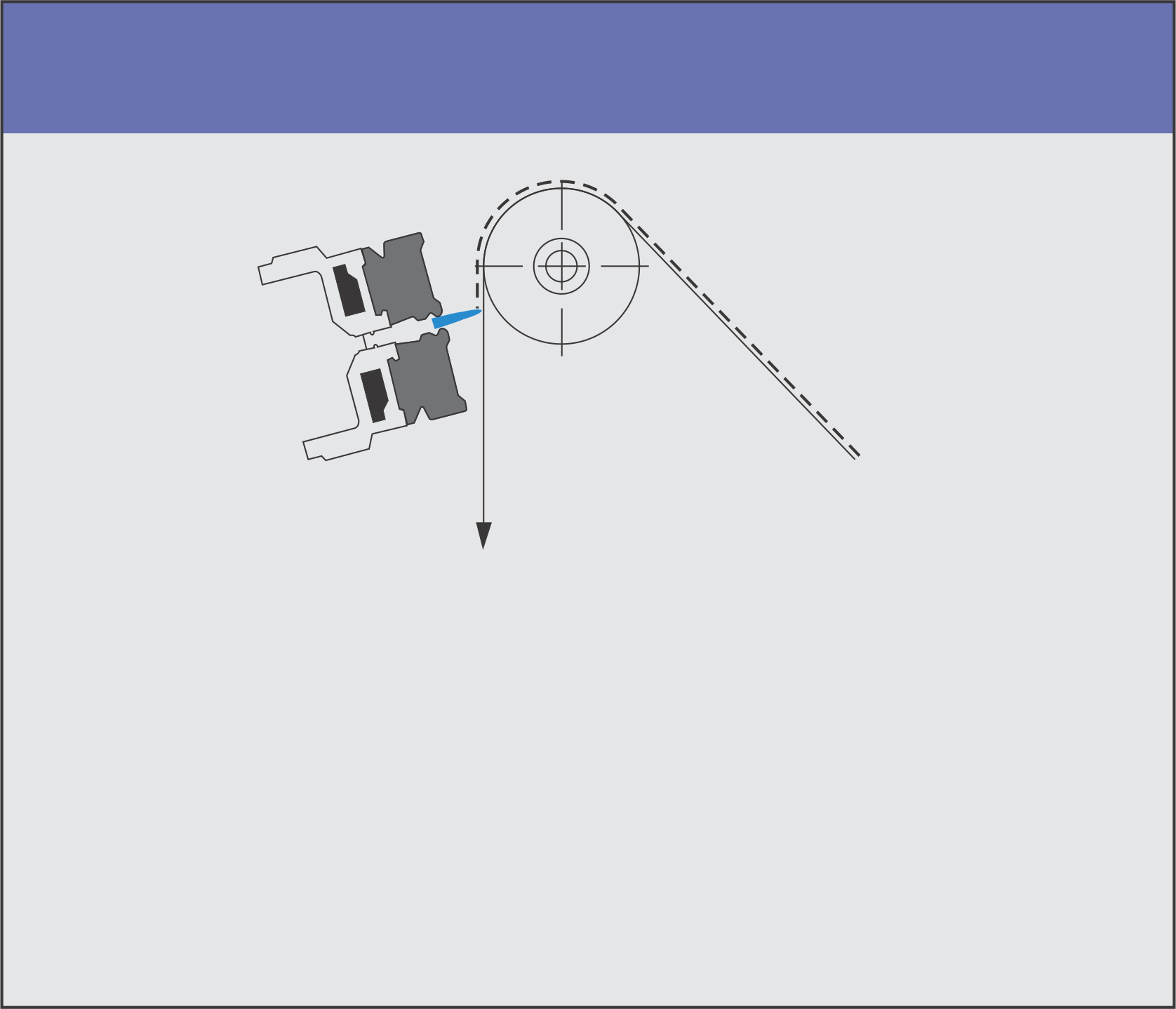

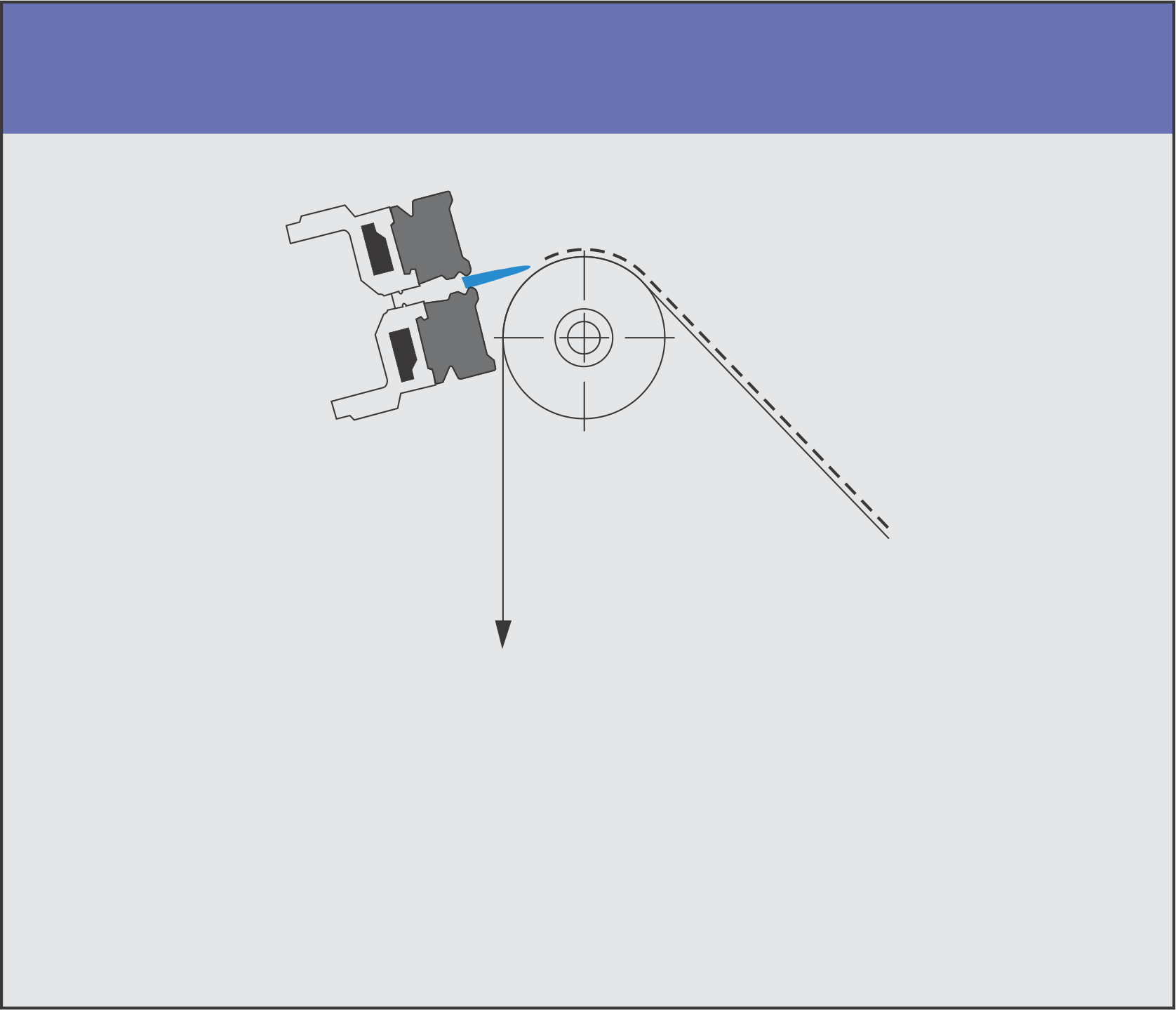

The singeing flame close to the fabric, but just missing the fabric surface, Suitable for heavier blends or heavier synthetic fabric. There are other parameters that inflame, in addition to the burner position . (a) Machine Speed. (b) Flame intensities. (c) Distance between burner & fabric and lastly (d) Fabric Temperature.

The singeing process is recommended for all materials which cannot tolerate direct exposure to flame. Tangential singeing can also equalize protruding fibers and repair filament breaks

Singeing Machines

Singeing Machines

ALSO AVAILABLE....