| Heating Medium | LPG OR NATURAL GAS |

| Fabric Width | 1800mm ( WW ) UPTO 3400mm |

| Roller Width | 2000mm up to 3600 mm |

| Machine Speed | 0 TO 130m / min. |

| Minimum Singeing Speed | 40 meter / min. |

| Water Pressure | 2 to 3 Bar |

| Gas Pressure | 0.3 to 3.0 Bar |

| Compressed Air | 6 Bar. |

| Electric Voltage | 415V, 3Phase, 50 HZ |

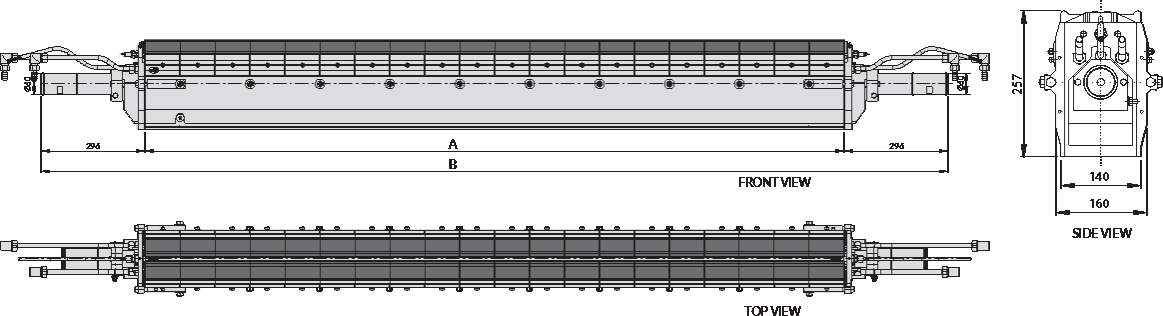

| BURNER WIDTH | W/W | A | B |

|---|---|---|---|

| 1800 mm | 1600 mm | 1800 | 2392 |

| 2000 mm | 1800 mm | 2000 | 2592 |

| 2200 mm | 2000 mm | 2200 | 2792 |

| 2400 mm | 2200 mm | 2400 | 2992 |

| 2600 mm | 2400 mm | 2600 | 3192 |

| 2800 mm | 2600 mm | 2800 | 3392 |

| 3000 mm | 2800 mm | 3000 | 3592 |

| 3200 mm | 3000 mm | 3200 | 3792 |

| 3400 mm | 3200 mm | 3400 | 3992 |

| 3600 mm | 3400 mm | 3600 | 4192 |

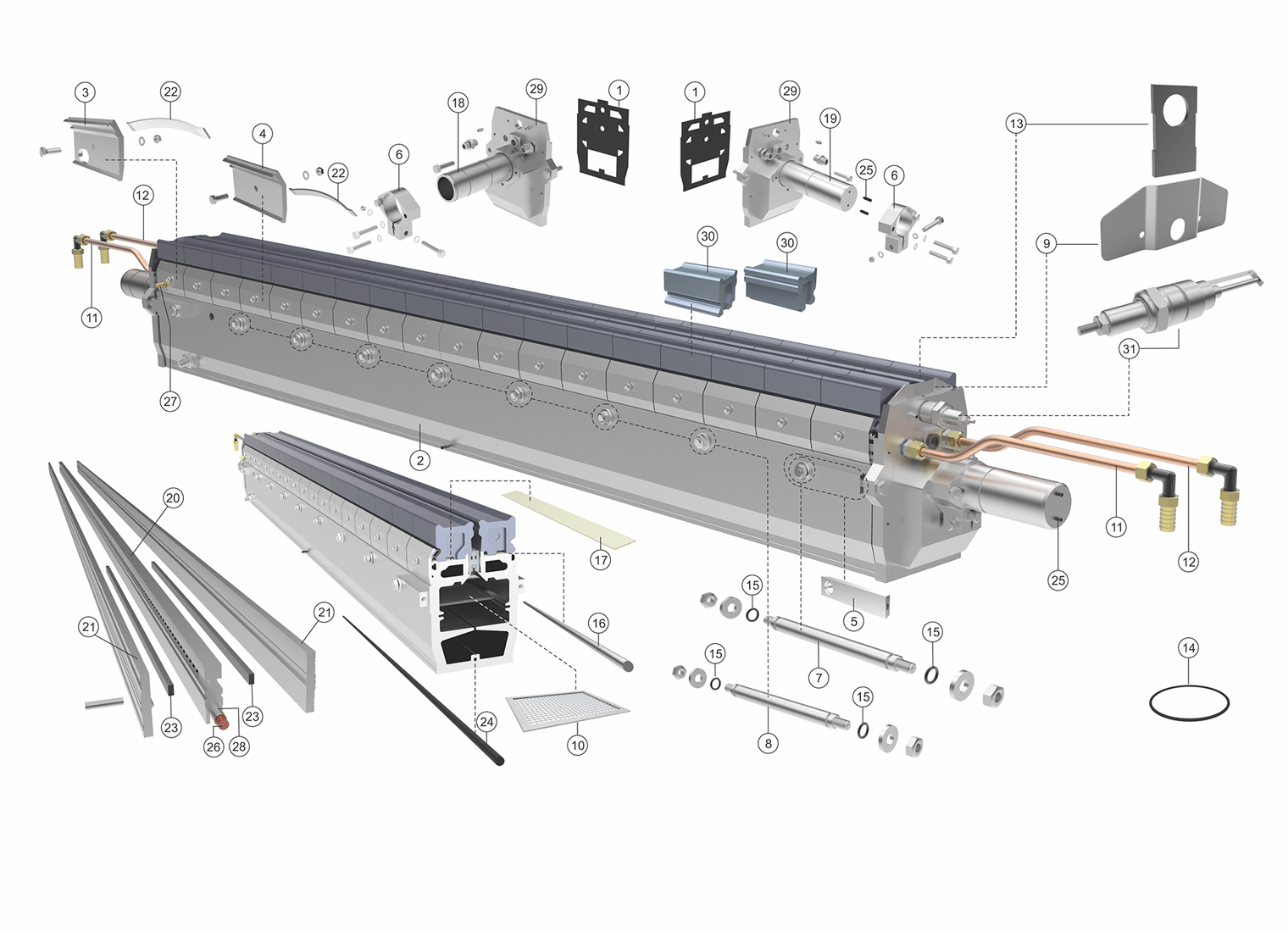

| POS. NO. | DESCRIPTION OF ITEMS | QUANTITY |

|---|---|---|

| 1 | FLANGE GASKET | 2 |

| 2 | BURNER BODY | 2 |

| 3 | CLAMP PLATE (WITH SLOT) | 2 |

| 4 | CLAMP PLATE (WITHOUT SLOT) | 34 |

| 5 | SUPPORT (25x15x110) | 4 |

| 6 | FIXING FLANGE | 2 |

| 7 | THREADED BOLT SHORT | 7 |

| 8 | THREADED BOLT LONG | 2 |

| 9 | FLAME SHIELDING PLATE | 2 |

| 10 | FLAT FILTER | 18 |

| 11 | INLET PIPE SMALL | 2 |

| 12 | INLET PIPE LONG | 2 |

| 13 | SEALING SET | 2 |

| 14 | CFT 'O' RING | 2 |

| 15 | O' RING (I.D.11 x Ø2.5) | 18 |

| 16 | ROUND ROD (Ø3x200) | 18 |

| POS. NO. | DESCRIPTION OF ITEMS | QUANTITY |

|---|---|---|

| 17 | SUPERWOOL ISOLATION STRIP (39x2x400) | - |

| 18 | SHAFT END - 1 | 1 |

| 19 | SHAFT END - 2 | 1 |

| 20 | BURNER MIDDLE RAIL (33.5x10x1796) | 1 |

| 21 | BURNER SIDE RAIL (36x7x1796) | 2 |

| 22 | SPRING STEEL STRIP | 18 |

| 23 | GASKET (3x6x285) | 2 |

| 24 | RUBBER CORD (Ø6x1800) | 1 |

| 25 | GRUB SCREW (M8x25) | 2 |

| 26 | SILICON RUBBER CORD FOR GAS SPRING | 1 |

| 27 | VENT SCREW - 1/8" | 1 |

| 28 | SPRING L-285 | 1 |

| 29 | BURNER FLANGE | 2 |

| 30 | BRICKS | 36 |

| 31 | SPARK PLUG | 1 |

| ROLLER WIDTH | W/W | A | B | C | EXHAUST FAN |

|---|---|---|---|---|---|

| 2000 mm | 1800 mm | 2000 | 2876 | 4010 | 4kw, 22m3/min, 1805pa |

| 2200 mm | 2000 mm | 2200 | 3076 | 4210 | 4kw, 22m3/min, 1805pa |

| 2400 mm | 2200 mm | 2400 | 3276 | 4410 | 4kw, 22m3/min, 1805pa |

| 3000 mm | 2800 mm | 3000 | 3876 | 5010 | 5.5kw, 66m3/min, 2345pa |

| 3200 mm | 3000 mm | 3200 | 4076 | 5210 | 7.5kw, 78m3/min, 2255pa |

| 3400 mm | 3200 mm | 3400 | 4376 | 5410 | 7.5kw, 78m3/min, 2255pa |

| ROLLER WIDTH | W/W | A | B | C | EXHAUST FAN |

|---|---|---|---|---|---|

| 2000 mm | 1800 mm | 2000 | 2876 | 3990 | 4kw, 22m3/min, 1805pa |

| 2200 mm | 2000 mm | 2000 | 3076 | 4190 | 4kw, 22m3/min, 1805pa |

| 2400 mm | 2200 mm | 2400 | 3276 | 4390 | 4kw, 22m3/min, 1805pa |

| 3000 mm | 2800 mm | 3000 | 3876 | 4990 | 5.5kw, 66m3/min, 2345pa |

| 3200 mm | 3000 mm | 3200 | 4076 | 5190 | 7.5kw, 78m3/min, 2255pa |

| 3400 mm | 3200 mm | 3400 | 4376 | 5390 | 7.5kw, 78m3/min, 2255pa |