LINE-1100 STENTER MACHINE

LINE-1100 STENTER MACHINE

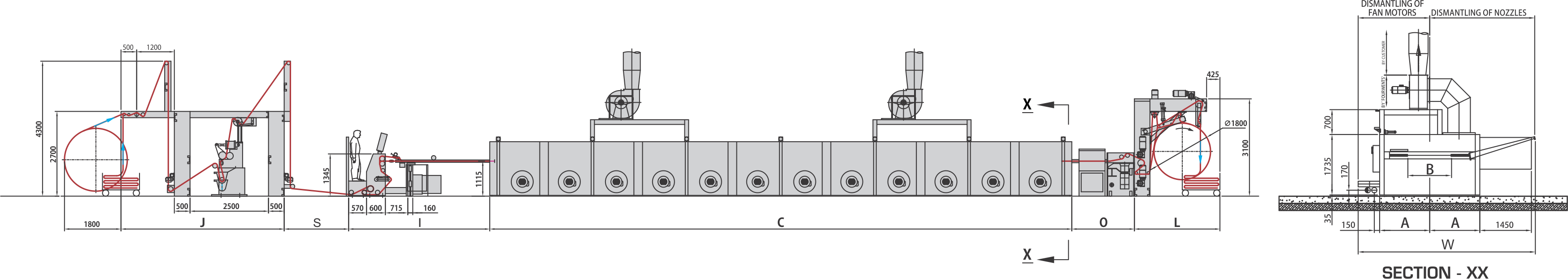

| INLET TRACK | I |

|---|---|

| STANDARD - 3000 | 4495 |

| OPTIONAL - 3900 | 5395 |

| EXTENSION ENTRY - 1440 | 5935 |

| EXTENSION ENTRY - 3000 | 7495 |

| OUTER TRACK | O |

|---|---|

| OPTIONAL - 1980 | 1970 |

| OPTIONAL - 2820 | 2810 |

| STANDARD - 3445 | STANDARD - 3445 |

| WEFT STRAIGHTENER | S |

|---|---|

| SPACE FOR WEFT STRAIGHTENER | 2050 |

| NO SPACE FOR WEFT STRAIGHTENER | 630 |

| NORMAL WIDTH | 1800 | 2000 | 2600 | 3400 |

|---|---|---|---|---|

| A | 1710 | 1810 | 2110 | 2510 |

| B | 1600 | 1800 | 2400 | 3200 |

| W (min) | 5620 | 5970 | 7220 | 8820 |

| NO. OF CHAMBER | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|

| SPACE FOR WEFT STRAIGHTENER | 10380 | 13380 | 16380 | 19380 | 22380 | 25380 | 28380 | 31380 |

| J - SCRAY | J | L | ||

|---|---|---|---|---|

| PADDER 1 No. | PADDER 2 No. | STD. OUTLET COMBINATION | WITH 2 DRIVEN COOLING CYLINDER | |

| WITH J-SCRAY | 5000 | 6800 | 6225 | 6625 |

| WITHOUT J-SCRAY | 5200 | 7000 | 2725 | 3125 |

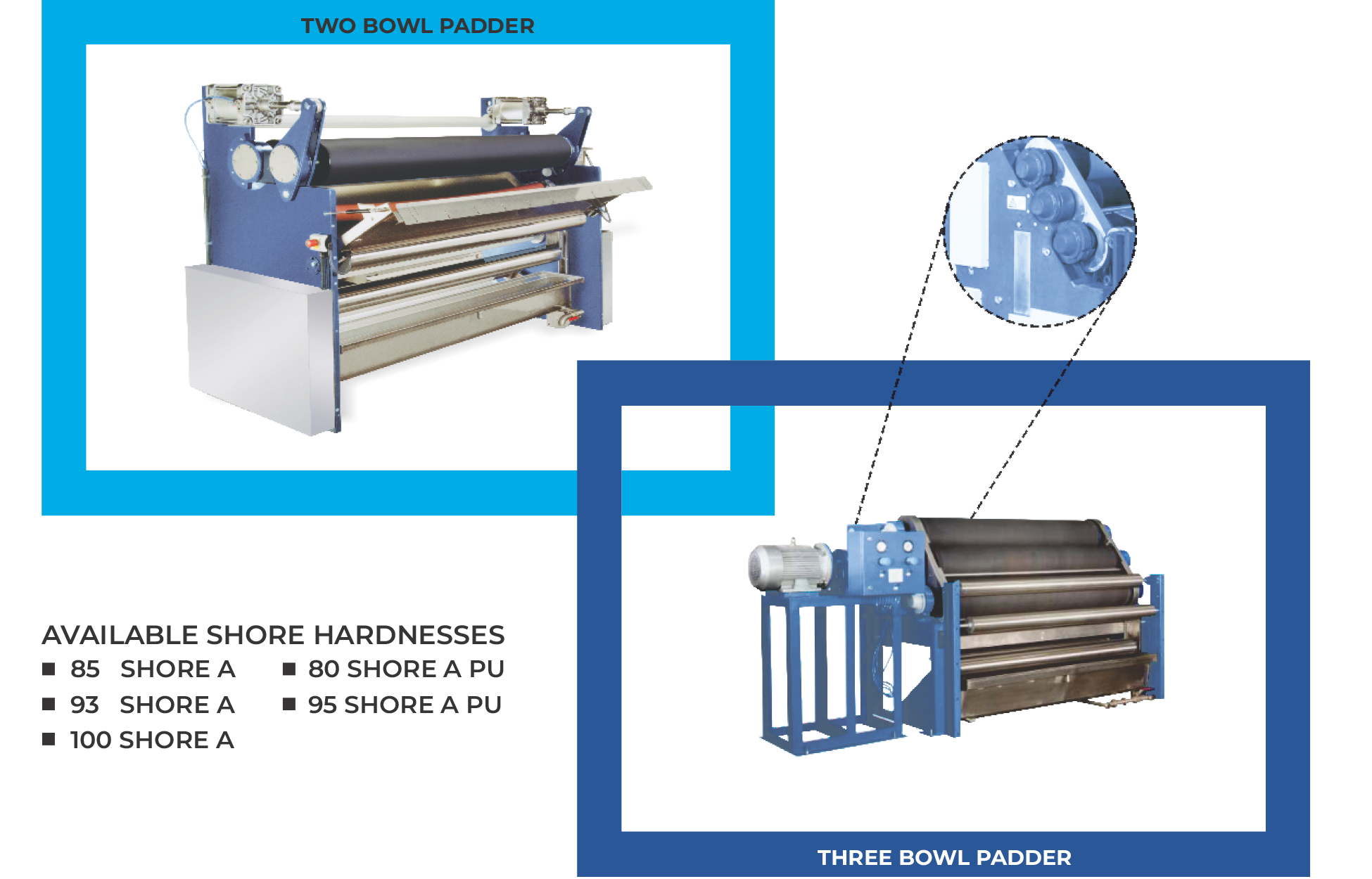

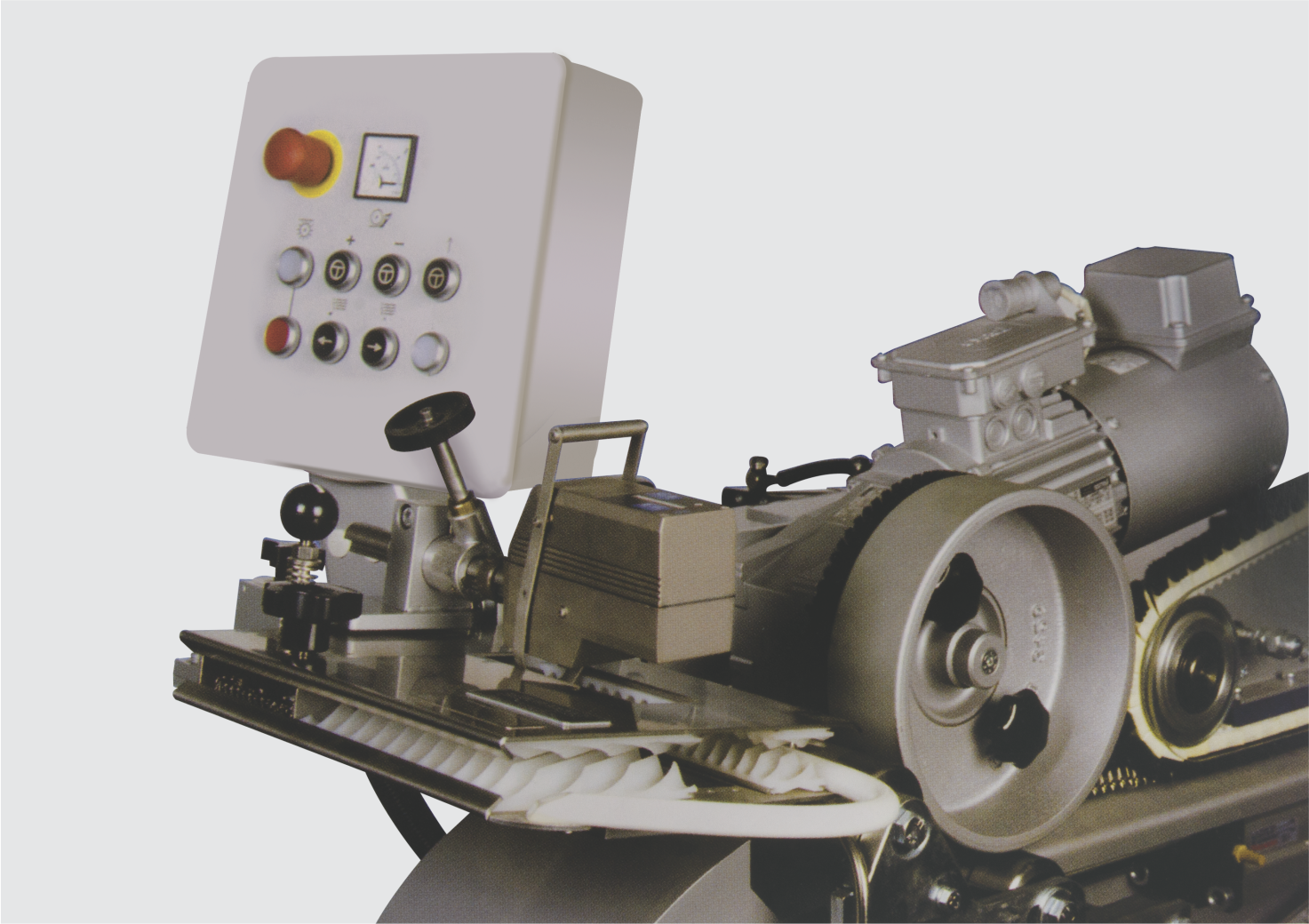

UNCURLING DEVICE & ROLLERS

UNCURLING DEVICE & ROLLERS

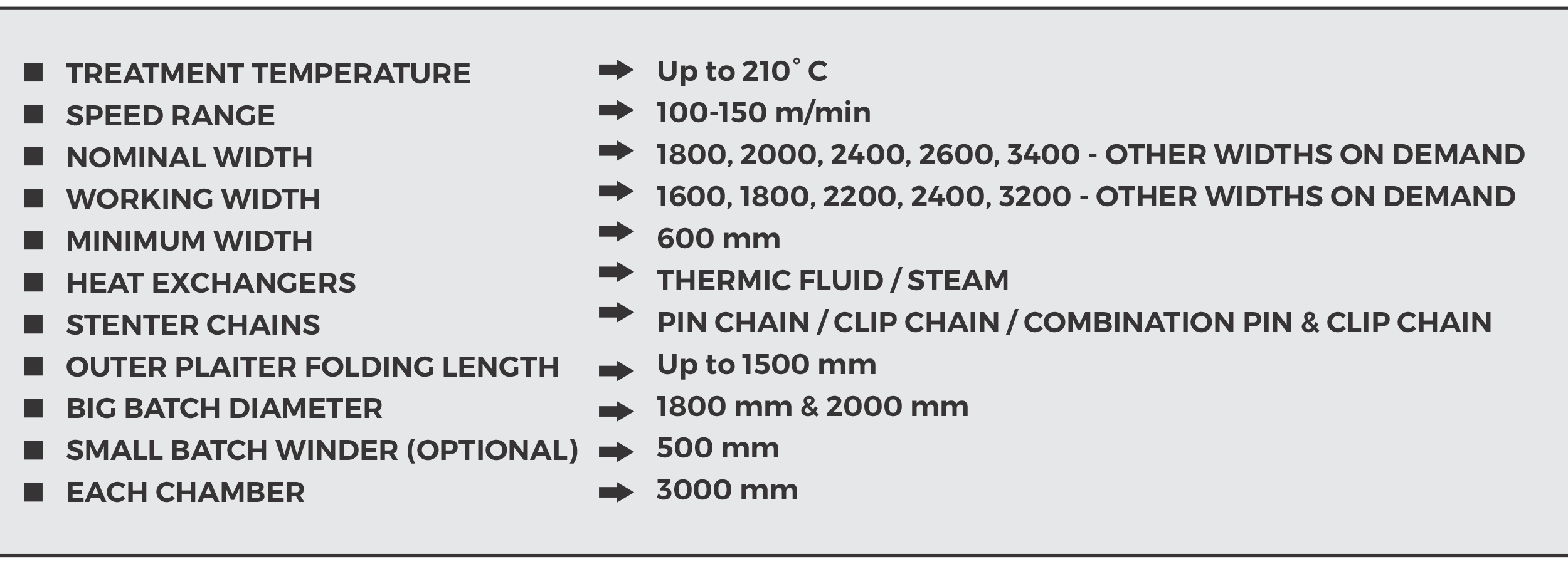

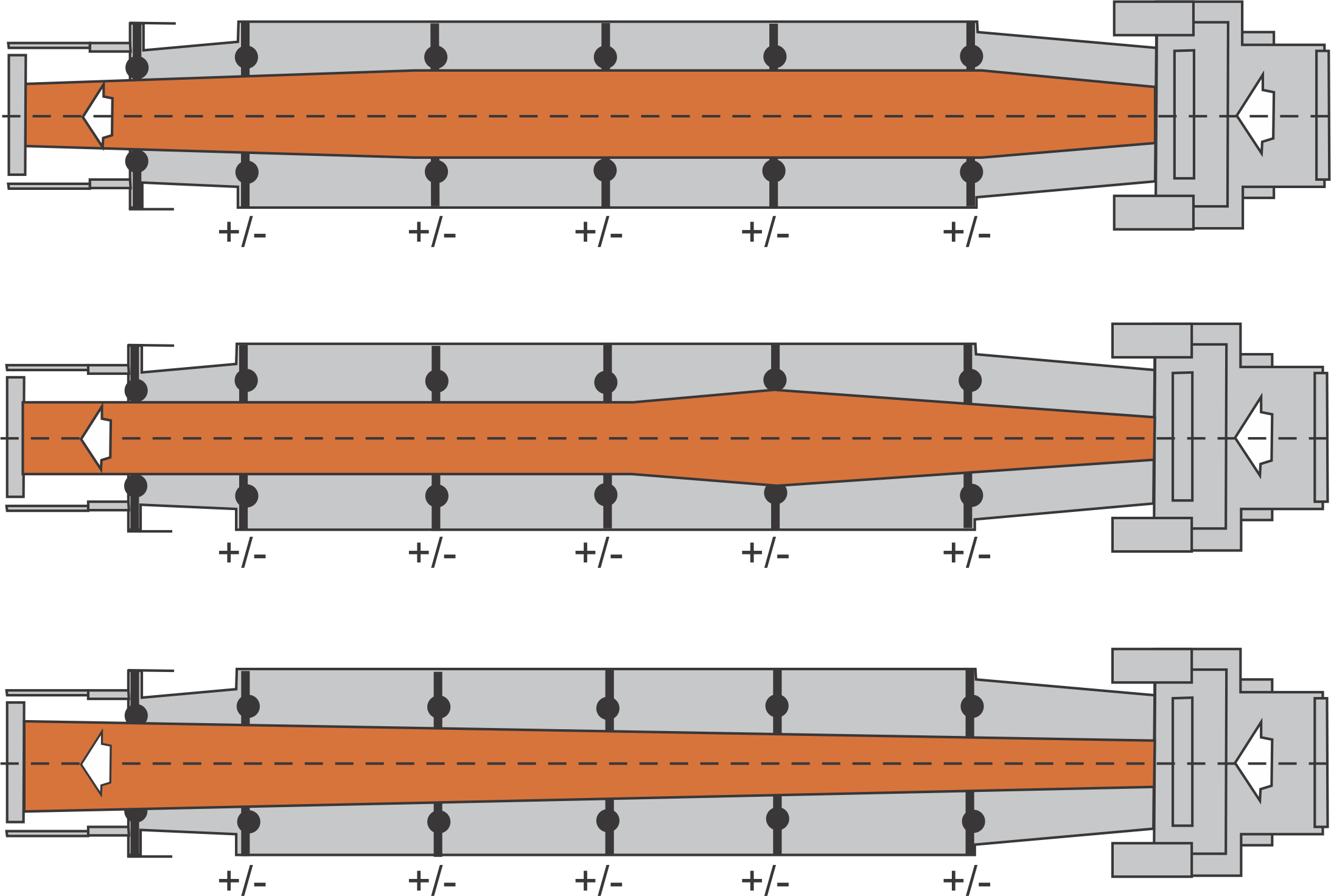

CHAIN TRACK ADJUSTMENT

EACH SPINDLE IS DRIVEN BY A SEPARATE MOTOR. ANY DESIRED WIDTH ADJUSTMENT THROUGH THE ENTIRE MACHINE CAN BE PROGRAMMED AND AUTOMATICALLY SET FROM A CENTRAL LOCATION.

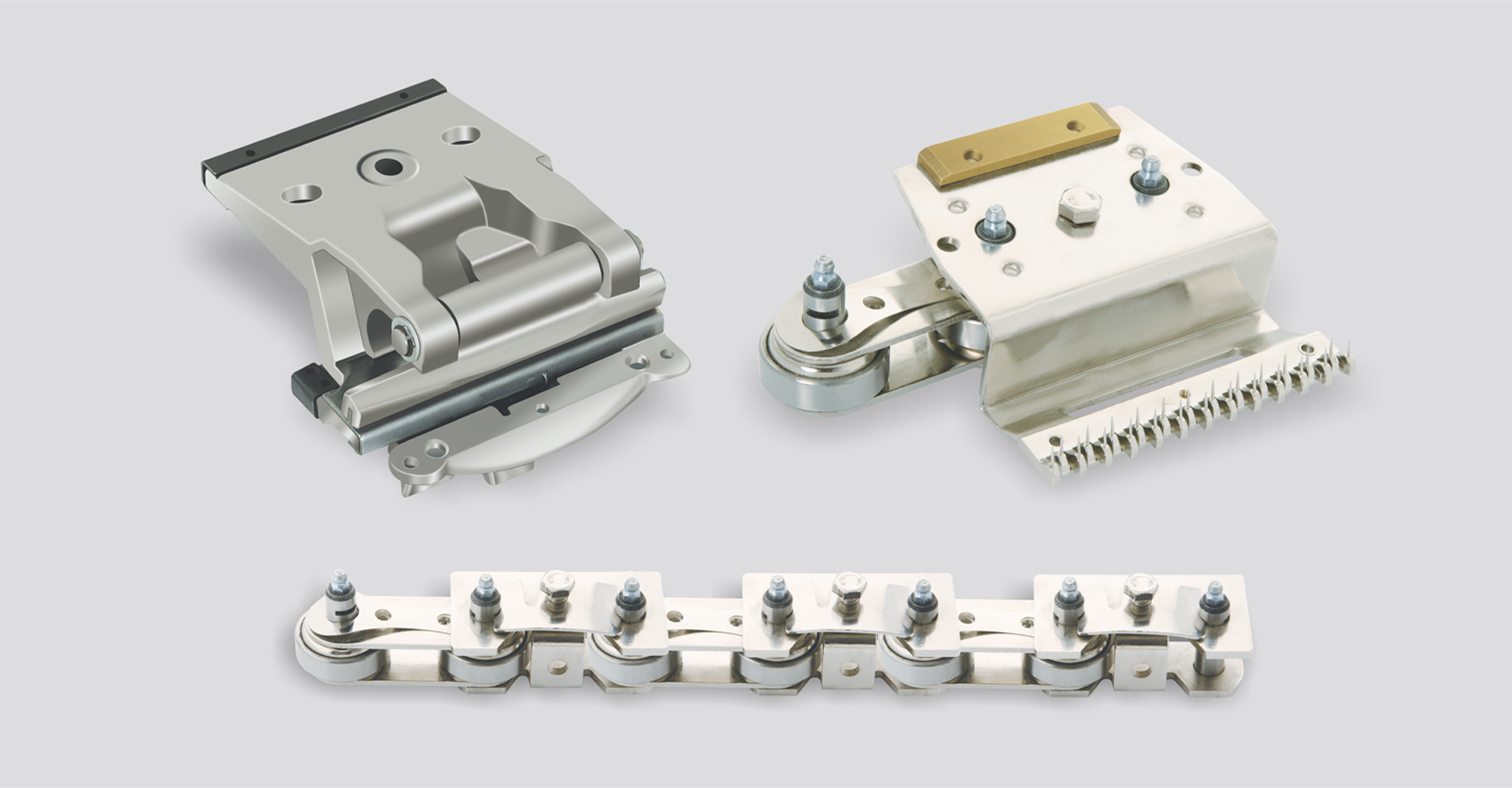

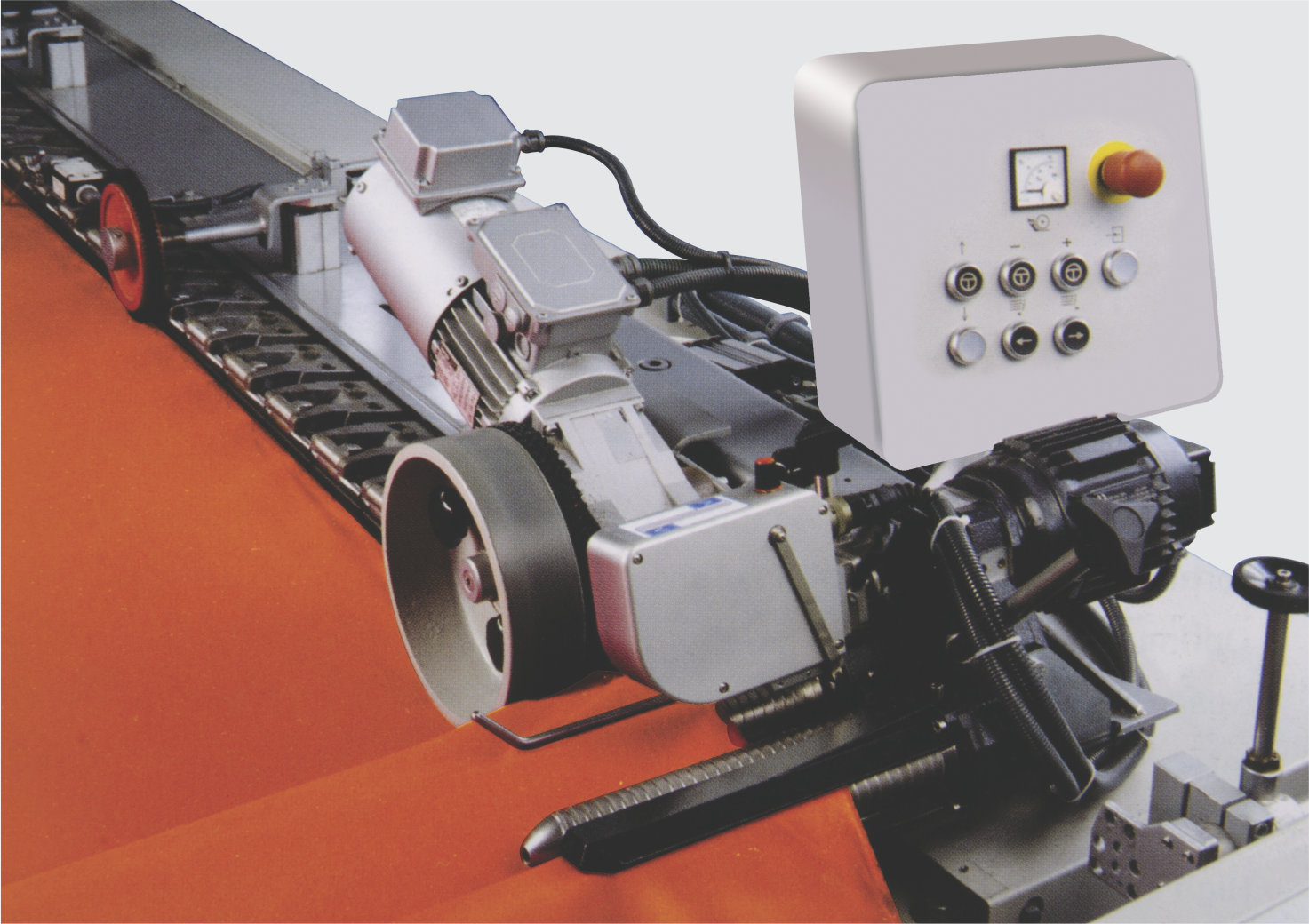

‘FOURWENTS’ COMBINED PIN CLIP ASSEMBLY COMPLETE PIN-LINK ASSEMBLY

WITH CHAIN-LINK & PIN PLATE / PIN BAR

SUITABLE FOR