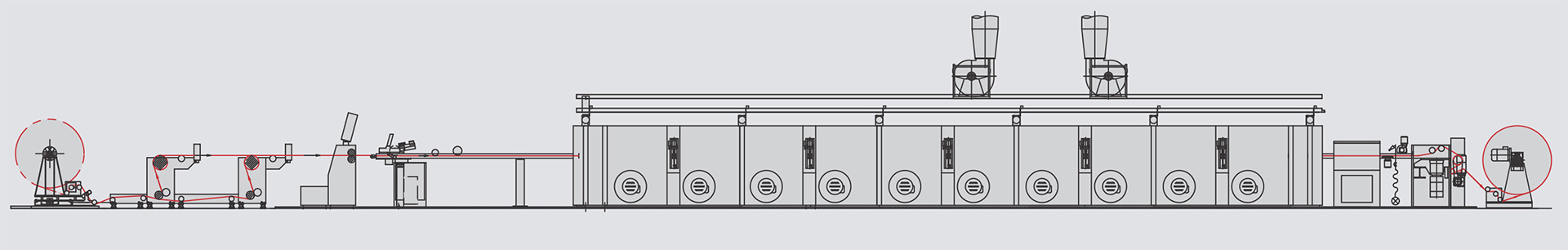

| TRANSPORT SYSTEMS | FOURWENTS PIN/CLIP OR COMBINED PIN CLIP. |

| MAXIMUM FABRIC WIDTH | UP TO 3200 MM |

| MINIMUM FABRIC WIDTH | 600 MM |

| SPEED RANGE | 5 TO 150 MTRS. / MIN. |

| TEMP. RANGE | 50° C TO 240° C |

| HEATING MEDIA | THERMAL OIL / STEAM |

| AIR PRESSURE | 6 BAR |

| CONTROL SYSTEM | “STENTOMATEX |

| FABRIC TAKE OFF | PIN / PIN PLUS CLIP / CLIP |

| CHAMBER | 6 No. TO 12 No. AND LENGTH 3MTR. PER CHAMBER |

| HEATING SYSTEM | OIL |

| SCARY | 350 METERS CLOTH CONTENT |

| PADDER | ROLL SQUEEZE DIA |

| MAX LINEAR PRESSURE | |

| 80/ 80 SHORE HARDNESS | |

| LIQUOR TROUGH | WATER JACKET / SINGLE WALL |

| TILTABLE | |

| AUTO LEVEL CONTROL | |

| LIQUOR VOLUME | |

| QUICK CLEANING SYSTEM | |

| STRAIGHTENING | BIANCO MAKE OR EQUIVALENT MAKE |

ALMOST 90% OF THE FIBERS (LINK TO TEXTILE FABRIC) UTILIZED TO TECHNICAL TEXTILES BELONG TO THE CATEGORY OF CONVENTIONAL FIBERS AND THE FIBERS SPECIALLY DEVELOPED TO SPECIFICALLY USE IN TECHNICAL TEXTILES ARE NOT ONLY EXPENSIVE BUT OFTEN HAVE LIMITED APPLICATIONS.

WITHIN THE COMPOSITES INDUSTRY, WOVEN, KNITTED, BRAIDED, NON WOVEN (LINK)AND WOUND REINFORCEMENTS PRODUCED FROM GLASS, CARBON FIBER AND ORGANIC POLYMER MATERIALS LIKE ARAMIDS ARE PRESENTLY ACCEPTED AS TECHNICAL TEXTILE PRODUCTS.