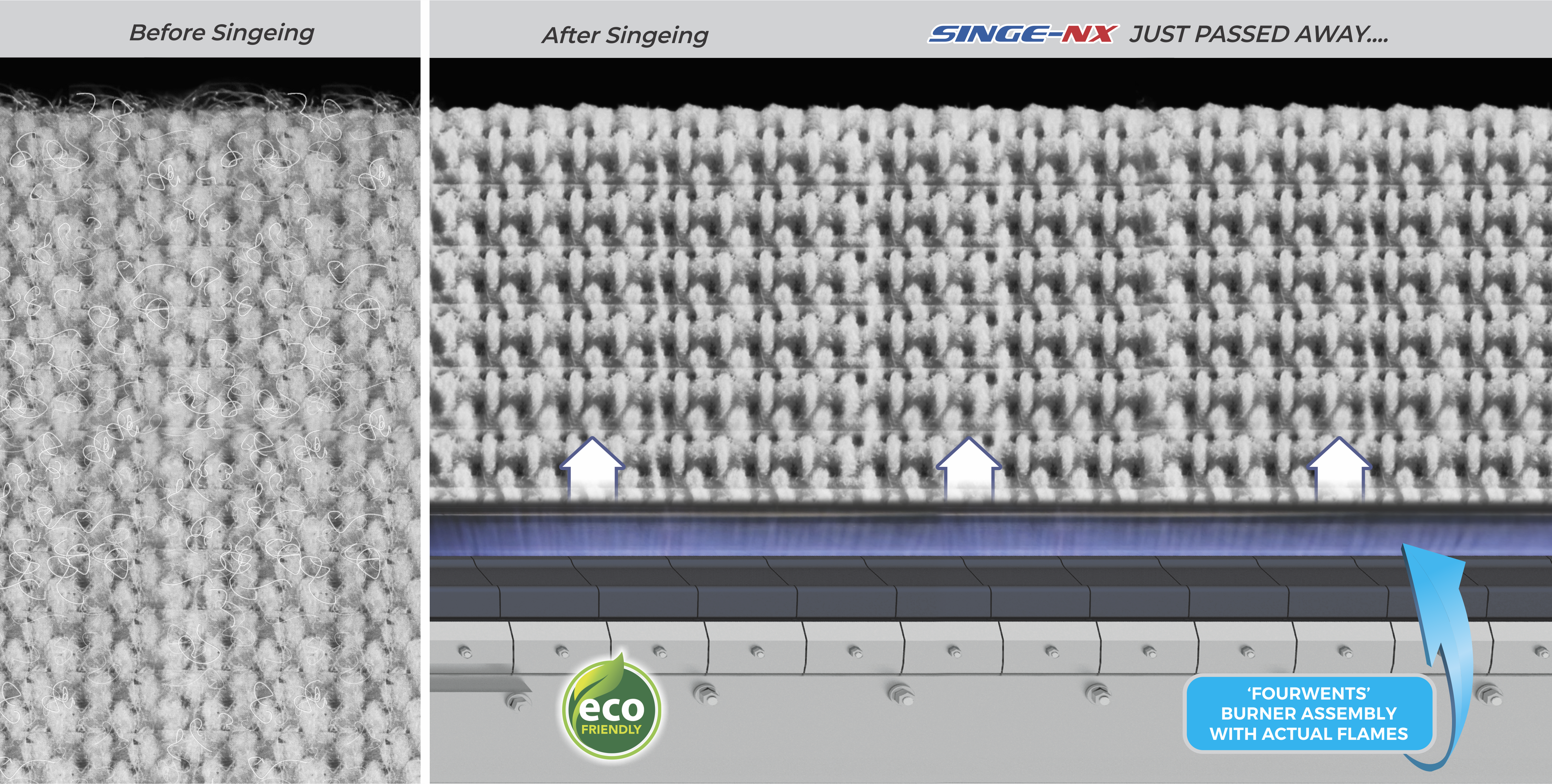

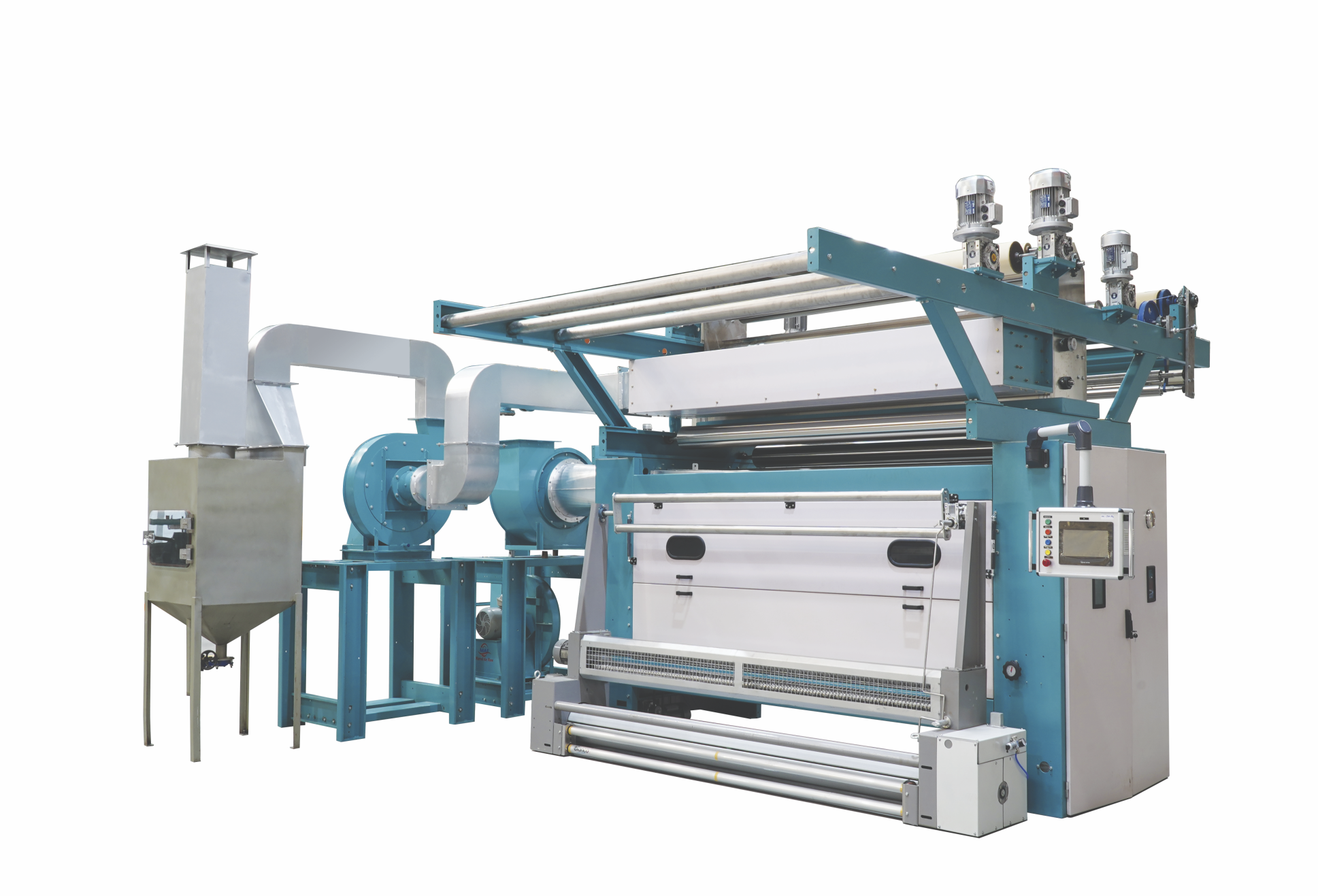

SINGEING IS THE PROCESS OF REMOVAL OF PROTRUDING FIBRES FROM THE SURFACE OF FABRIC THROUGH THE APPLICATION OF OPEN FLAMES WHILE THE FABRIC IS IN MOTION. THE FUEL TYPICALLY USED IS LPG, WITH A DEFINED RATIO OF GAS TO AIR. SINGEING HELPS IMPROVE THE FABRIC’S APPEARANCE AND REDUCES ITS TENDENCY TO FORM PILLS; THIS ALSO HELPS PREVENT THE SURFACE OF THE FABRIC FROM PICKING UP DIRT. THE SINGEING PROCESS IS PERFORMED IN THE GREY STAGE ITSELF, IN ORDER TO TAKE ADVANTAGE OF THE DRY STATE OF THE FABRIC. ALSO, SINGED FABRIC ALSO CAN BE DYED AND PROCESSED BETTER.

SINGEING IS A WIDELY ACCEPTED PROCESS IN THE WOVEN PROCESSING INDUSTRY. HOWEVER, IN THE KNIT PROCESSING INDUSTRY, SINGEING IS DIFFICULT TO PERFORM ON FABRICS IN TUBULAR FORM AS THE FLAME TO FABRIC DISTANCE IS HARD TO CONTROL ACCURATELY, WHICH RESULTS IN UNEVEN SINGEING.

IN ORDER TO IMPART TO TUBULAR KNIT FABRICS, THE SAME KIND OF FINISH ACHIEVED THROUGH SINGEING IN WOVEN FABRICS, THE SURFACE OF THE KNITTED FABRIC IS CLEANED IN A SOFT FLOW DYEING MACHINE THROUGH BIO-POLISHING.

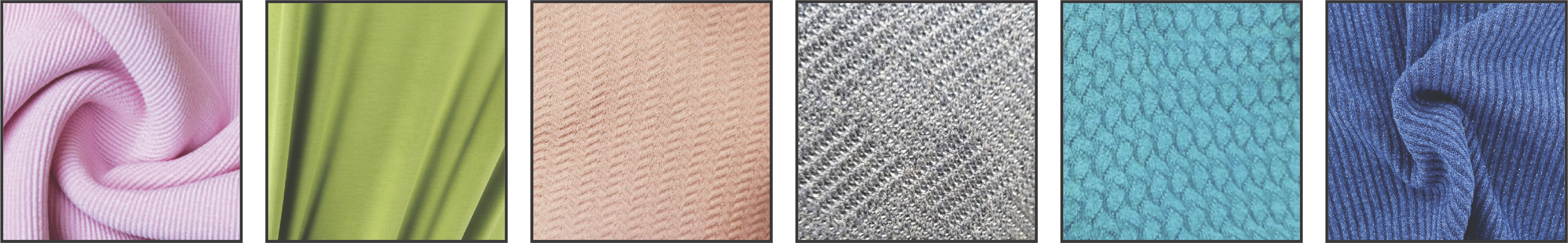

KNIT FABRIC

KNIT FABRIC