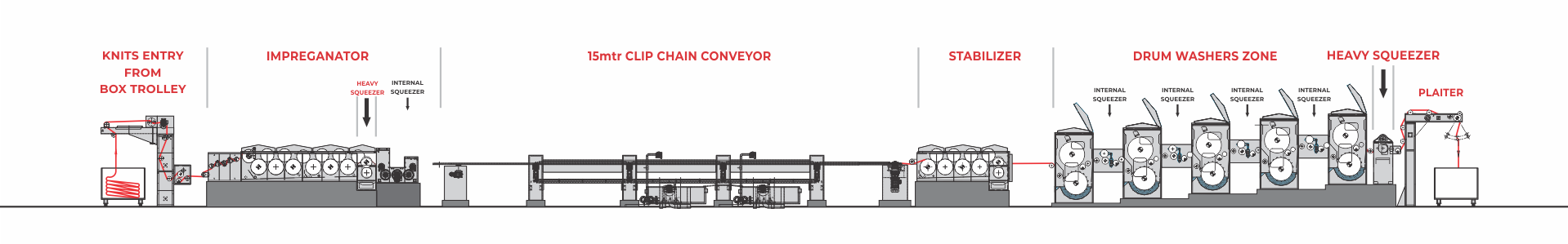

TECHNICAL AND UTILITY DATA OF NEXUS’ KNIT CHAIN MERCERIZER

(1) PROCESS: Dry on Wet/ Wet on Wet, Room Mercerizing

( Hot/Cold Optional )

(2) FABRIC QUALITY : 100 % Cotton, Cotton / Viscose blends at lower caustic strengths

(3) PRODUCTION SPEED: 20 - 30 or 30 - 40 metres per minute configuration available.

| CHEMICALS: Caustic soda |

| CAUSTIC CONSUMPTION: Approx. 240 gm/kg of fabric @ 25 Be |

| WATER CONSUMPTION: Approx. 5 - 6 L/kg of fabric |

| STEAM CONSUMPTION: Approx. 0.5 - 0.6 kg/kg of fabric |

| TEMPERATURE |

| TIME |

| LYE (NaOH) |

| LYE PENETRATION |

| APPLICATION |

| Cold Mercerizing |

| 25 degree C |

| 50 - 60sec. |

| 25 - 28Be |

| Slow |

| Yarn Dye/Dye Fabric |

| Room Mercerizing |

| 40 - 45 Degree C |

| 45 sec. |

| Medium |

| Grey Fabric |

| Hot Mercerizing |

| 60 Degree C |

| 30 sec. |

| Fast |

| Grey Fabric |

‘NEXUS’ CHAIN MERCERIZING RANGE IS USED FOR TEXTILE PROCESSING OF OPEN WIDTH PREMIUM COTTON KNITTED FABRIC WITH HIGH QUALITY & PRODUCTIVITY. THE RANGE HAS EQUIPPED WITH AN OPTIMUM LENGTH OF PIN CHAIN SECTION FOR CONTROLLING THE WIDTH-WISE DENSITY OF FABRIC. ‘NEXUS’ CHAIN MERCERIZING RANGE GIVES FASTEST MERCERIZED EFFECT ON COTTON FIBERS WITH RESULTS OF DEEPER SHADE IN REACTIVE DYED OR PRINTED FABRICS.