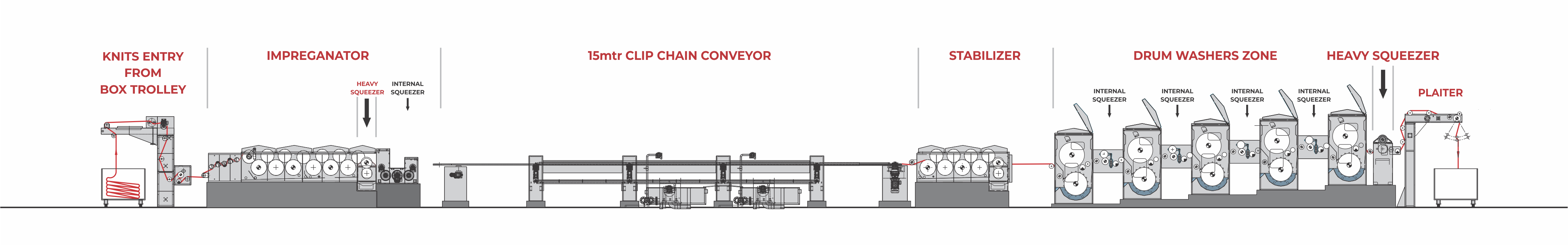

(1) PROCESS: Dry on Wet/ Wet on Wet, Room Mercerizing ( Hot/Cold Optional ).

(2) FABRIC QUALITY: 100 % Cotton, Cotton / Viscose blends at lower caustic strengths.

(3) PRODUCTION SPEED: 20 - 30 or 30 - 40 metres per minute configuration available.

CHEMICALS: Caustic Soda

CAUSTIC CONSUMPTION: Approx. 240 gm/kg of fabric @ 25 Be

WATER CONSUMPTION: Approx. 5 - 6 L/kg of fabric

STEAM CONSUMPTION: Approx. 0.5 - 0.6 kg/kg of fabric

NEXUS CHAIN MERCERIZING RANGE IS USED FOR TEXTILE PROCESSING OF OPEN WIDTH PREMIUM COTTON KNITTED FABRIC WITH HIGH QUALITY & PRODUCTIVITY. THE RANGE HAS EQUIPPED WITH AN OPTIMUM LENGTH OF PIN CHAIN SECTION FOR CONTROLLING THE WIDTH-WISE DENSITY OF FABRIC. ‘NEXUS’ CHAIN MERCERIZING RANGE GIVES FASTEST MERCERIZED EFFECT ON COTTON FIBERS WITH RESULTS OF DEEPER SHADE IN REACTIVE DYED OR PRINTED FABRICS.

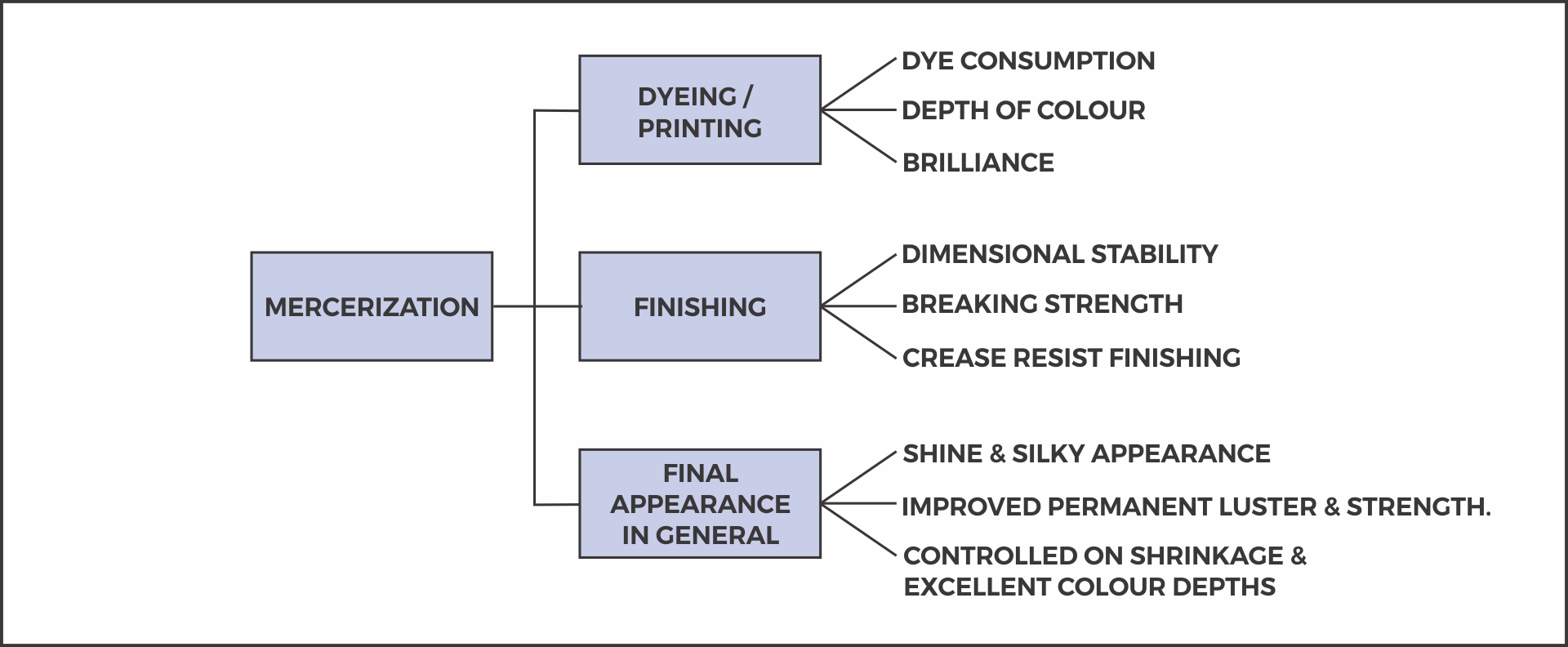

MERCERIZATION AND IT IMPORTANCE:

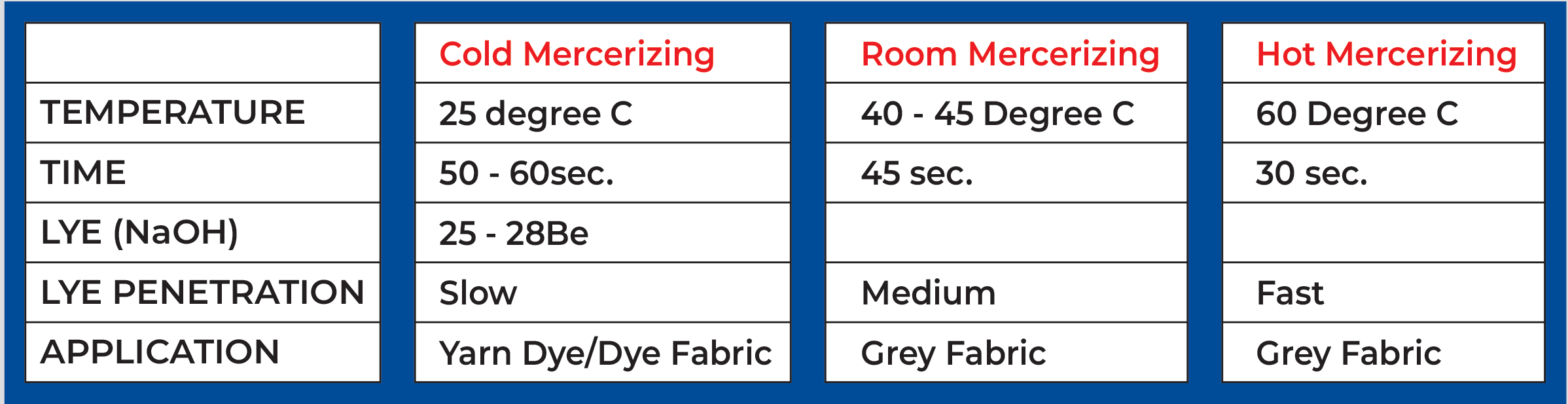

IMPREGNATION OF COTTON, IN THE FORM OF YARN OR FABRIC, WITH SODIUM HYDROXIDE SOLUTION (CAUSTIC SODA) AT A CONCENTRATION IN THE RANGE 200-220 GPL (GRAMS PER LITRE) AT 20°C OR 60°C UNDER CERTAIN TENSIONIS CALLED MERCERISATION.

THE FOLLOWING PROPERTIES ARE IMPROVED AFTER MERCERIZATION:

TYPES OF FABRIC MERCERIZATION:

1. CHAIN MERCERIZATION MACHINE

2. CHAINLESS MERCERIZATION MACHINE

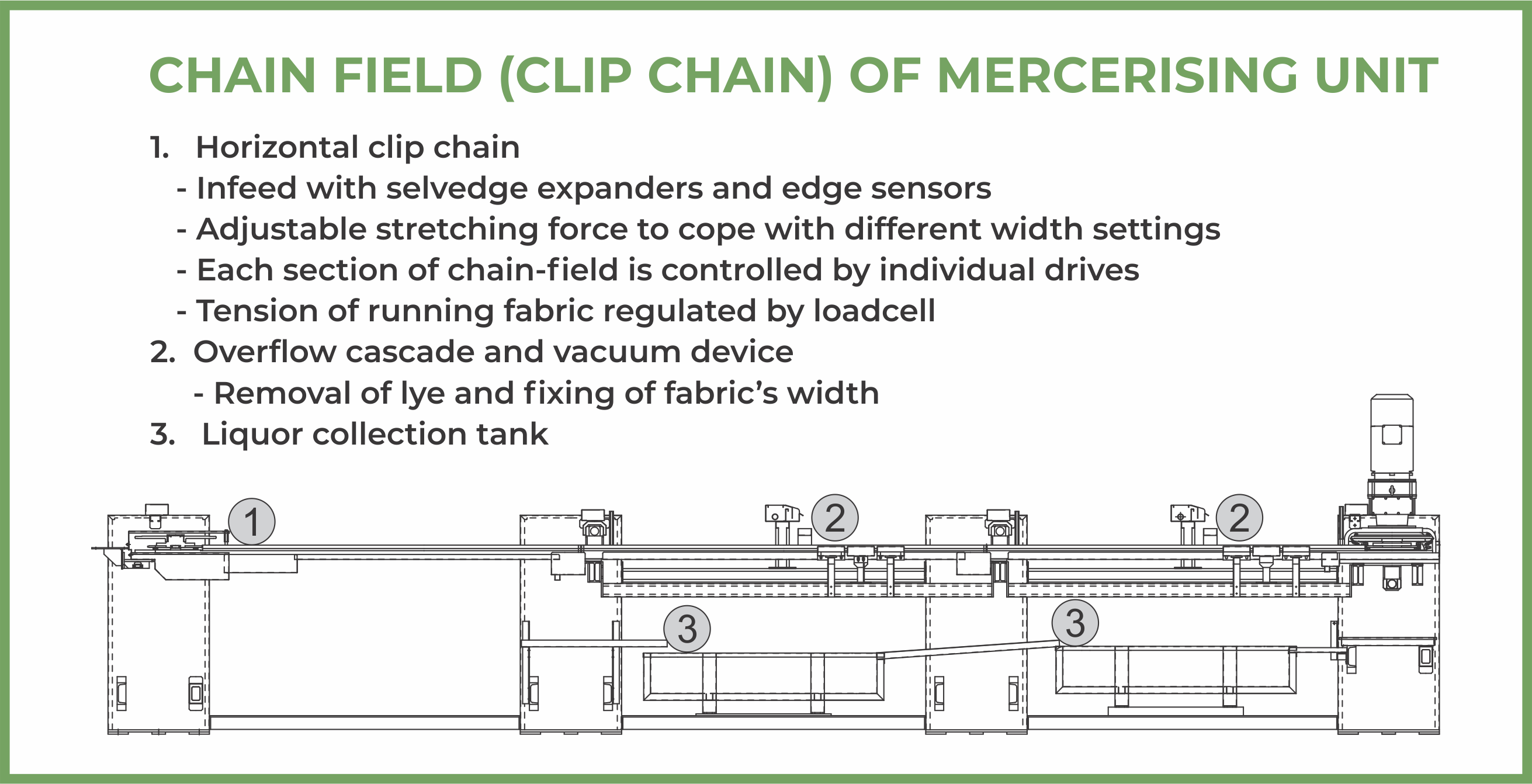

CHAIN MERCERIZING IS DONE ON A RANGE EQUIPPED WITH TENTER CHAINS FOR TENSION CONTROL. THE RANGE CONSISTS OF A PAD MANGLE FOLLOWED BY A SET OF TIMING CYLINDERS AND THEN A CLIP TENTER FRAME.

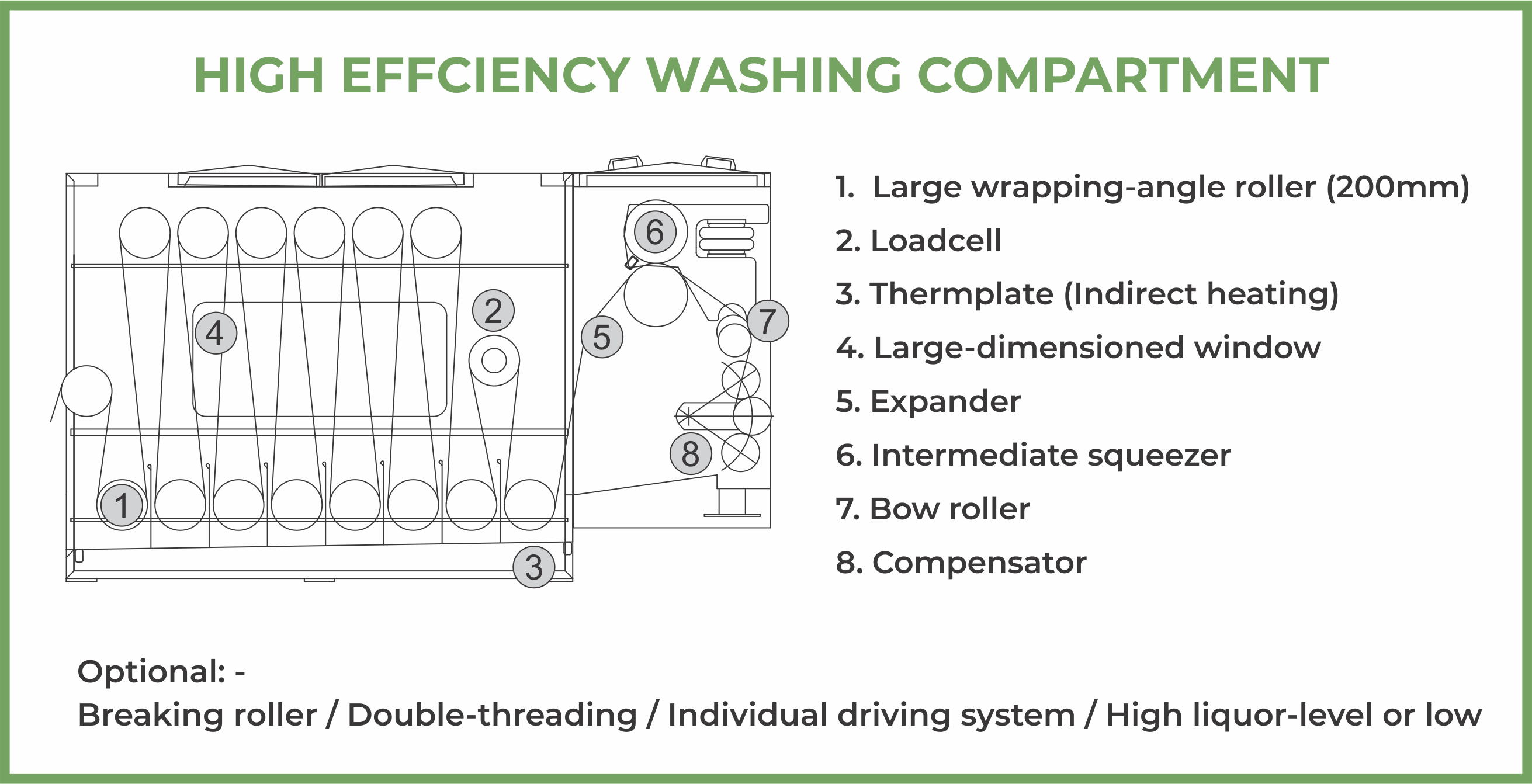

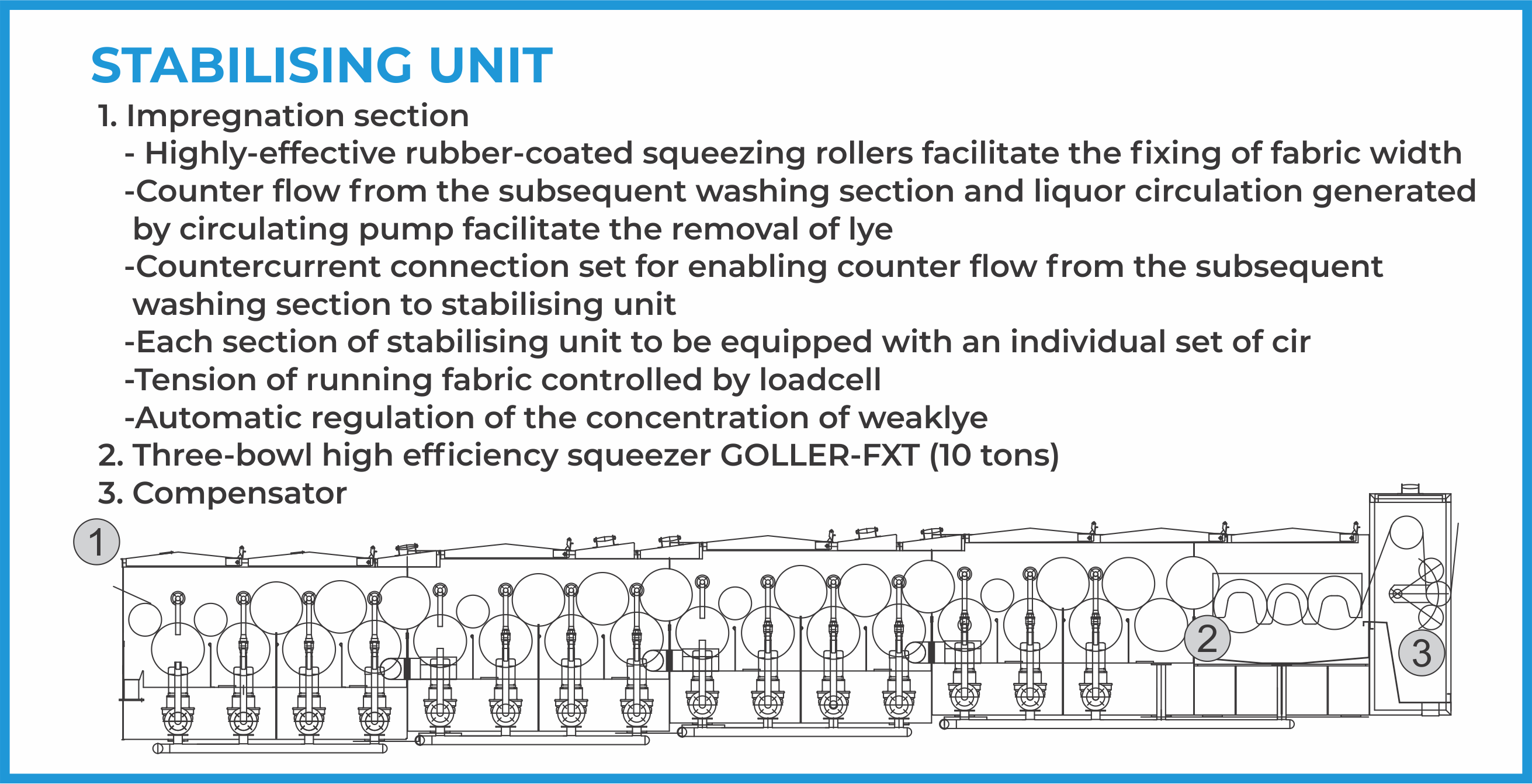

FRESH WATER IS SPRAYED ONTO THE FABRIC TO REMOVE THE CAUSTIC SODA AS IT IS HELD TENSIONED IN THE TENTER FRAME. THE TENTER FRAME IS FOLLOWED BY A SERIES OF OPEN WIDTH WASH BOXES WHICH FURTHER REDUCES THE CAUSTIC LEVEL. ACETIC ACID IS IN ONE OF THE LAST BOXES TO COMPLETE THE NEUTRALIZATION OF CAUSTIC.

DUAL BENEFITS OF MERCERIZING OPEN WIDTH KNITTED AS WELL AS WOVEN FABRICS INCREASED ABSORBENCY OF KNITTED FABRICS IMPROVES LUSTRE OF THE KNITTE FABRICS INCREASED DIMENSION STABILITY OF THE KNITTED FABRICS INCREASED DYE ABILITY. 15-20% LESS DYE CONSUMPTION COMPARED TO UN-MERCERIZED KNITTED FABRICS EXCELLENT APPEARANCE POST DYEING AND PRINTING .

MERCERIZATION IS A PROCESS IN WHICH THE KNITTED AS WELL AS WOVEN FABRIC IS TREATED WITH CERTAIN PERCENTAGE OF LIQUID CAUSTIC TO INCREASE ITS STRENGTH, ANTI-SHRINK QUALITY, LUSTER AND INCREASED DYE AFFINITY.

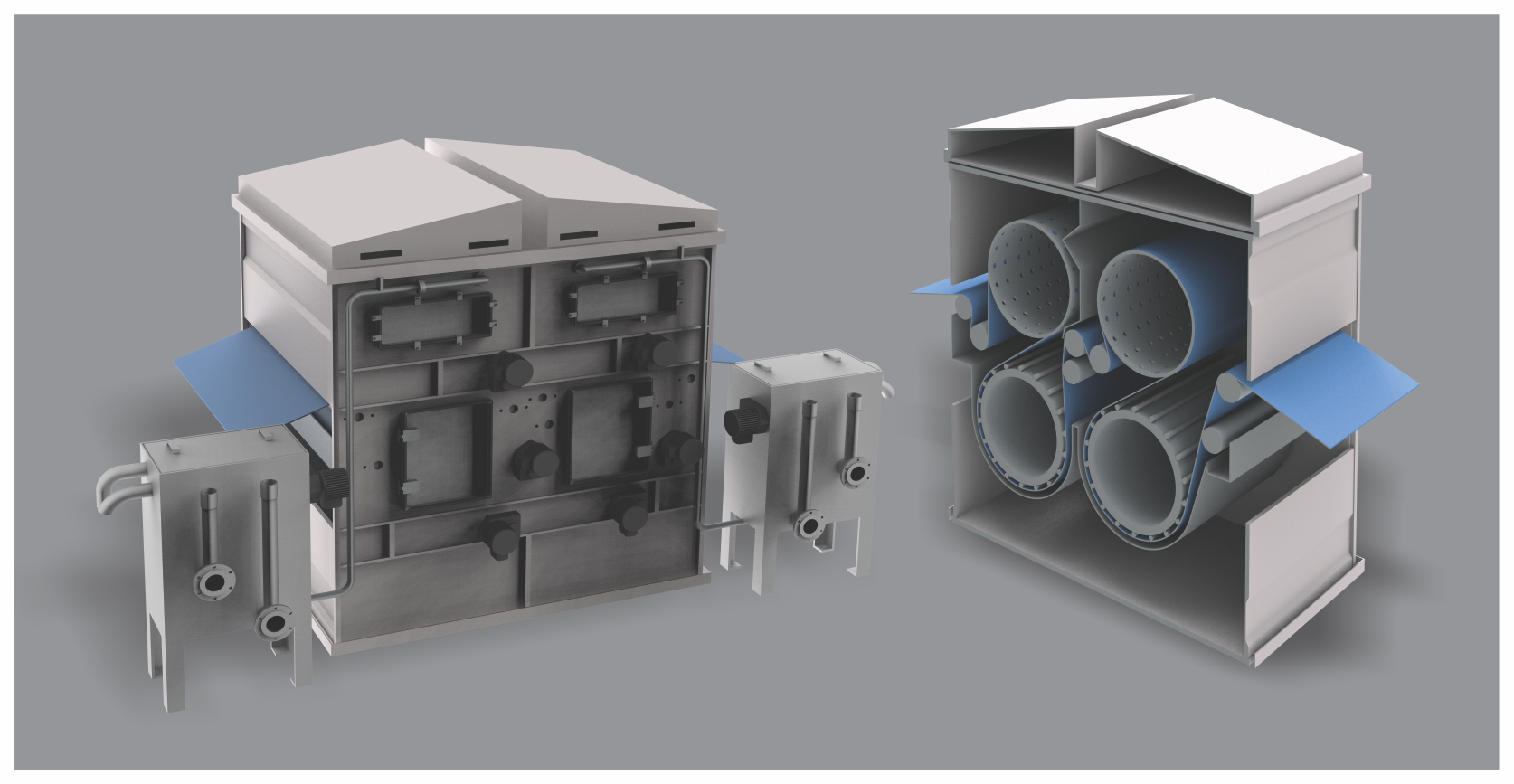

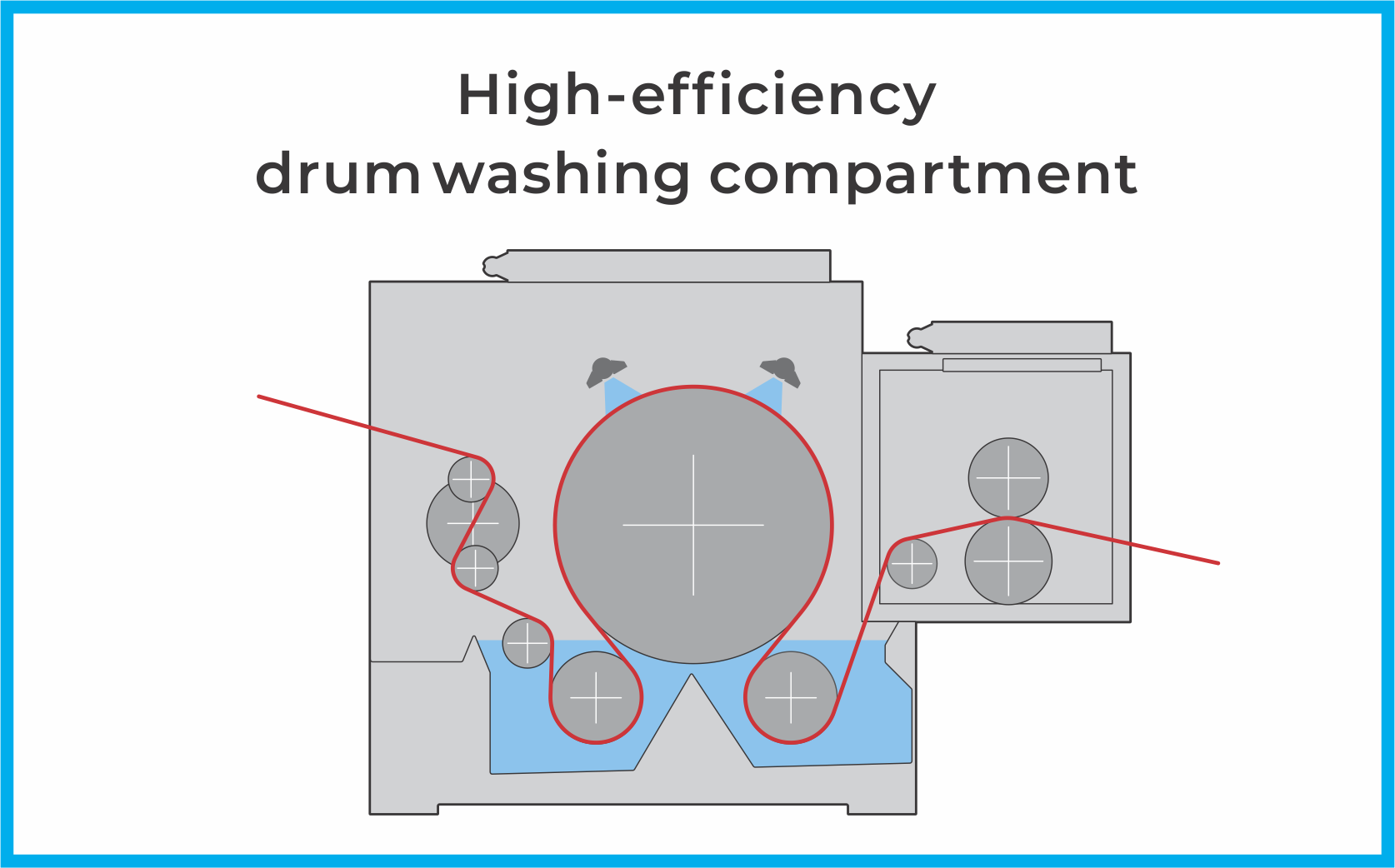

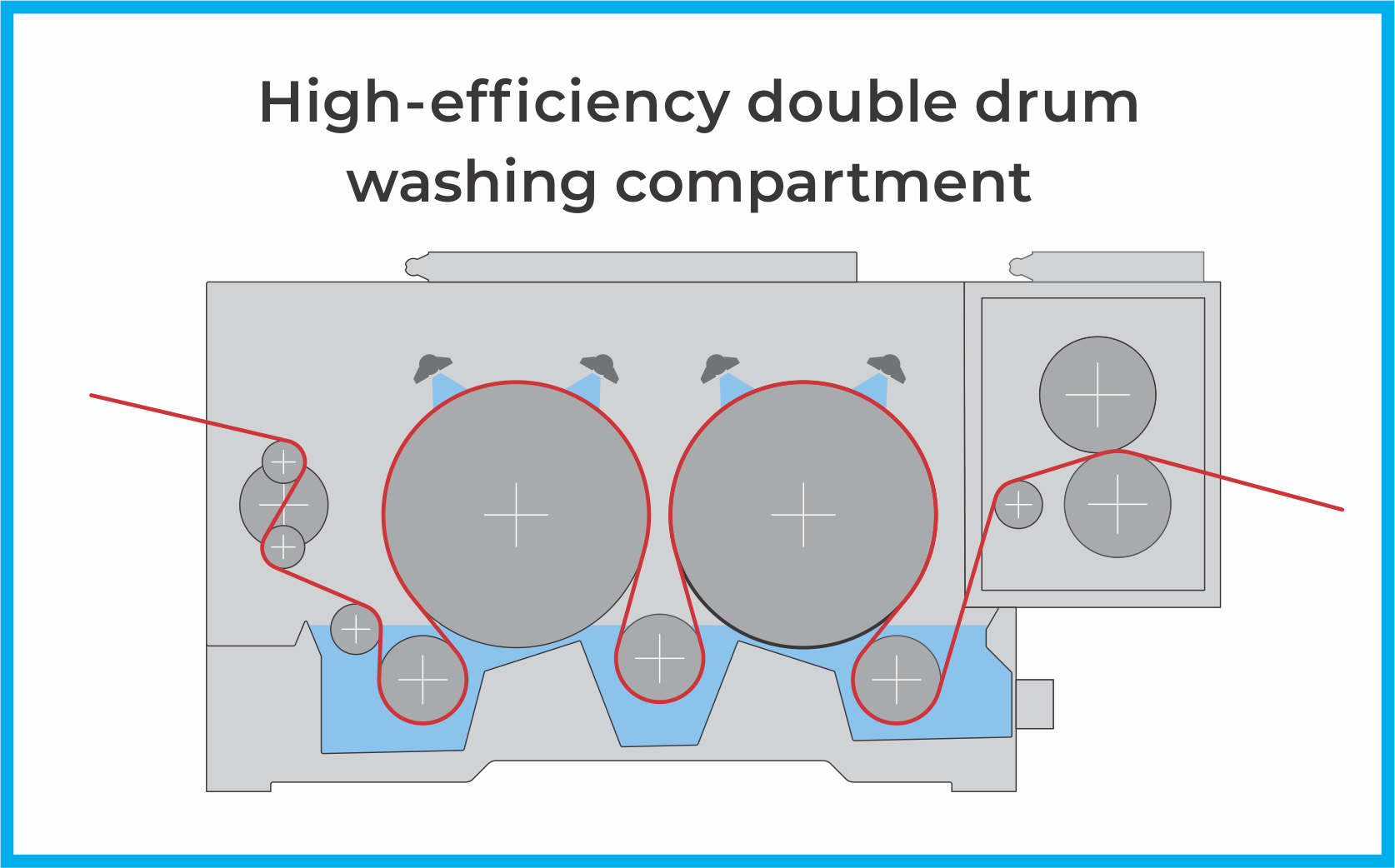

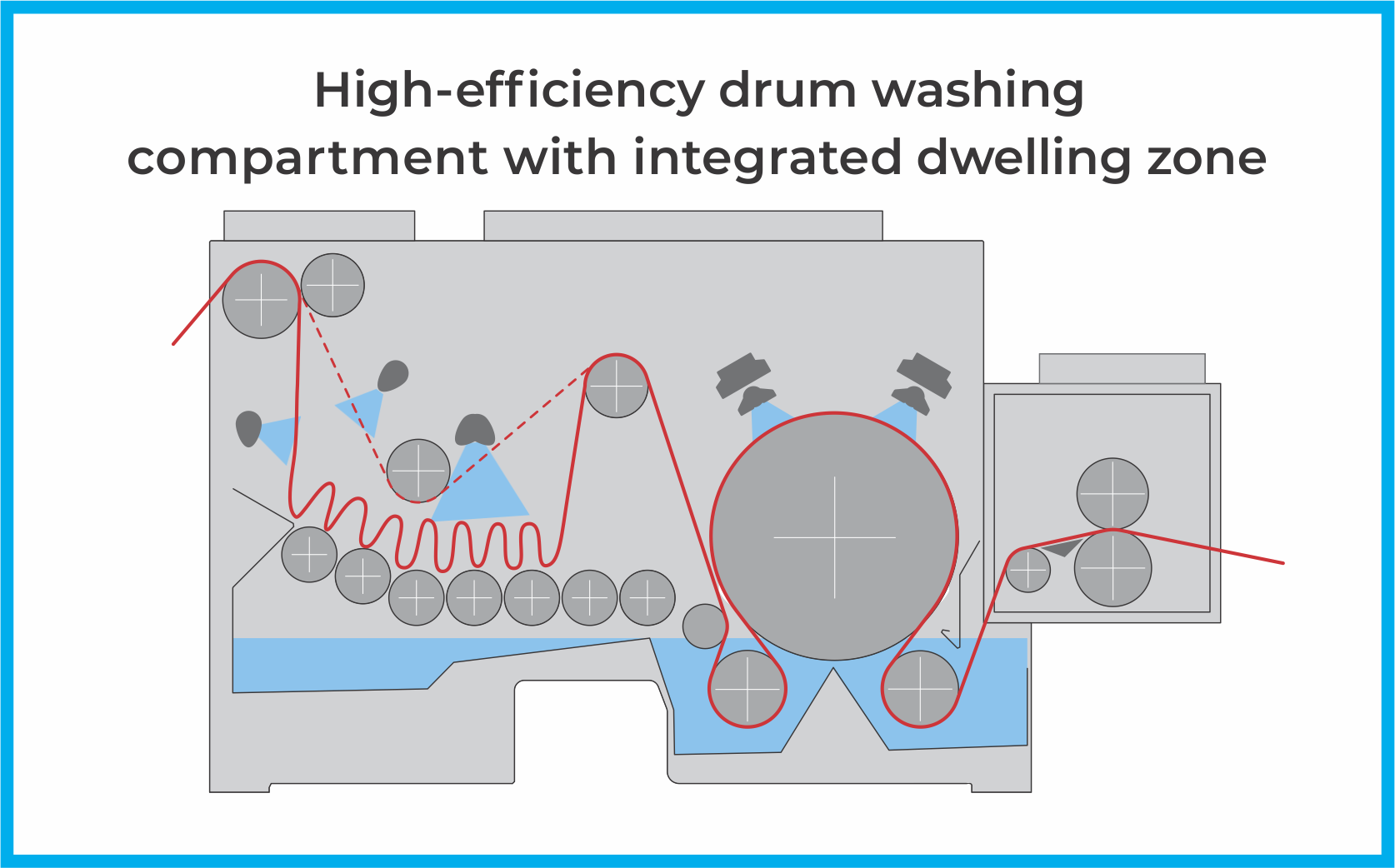

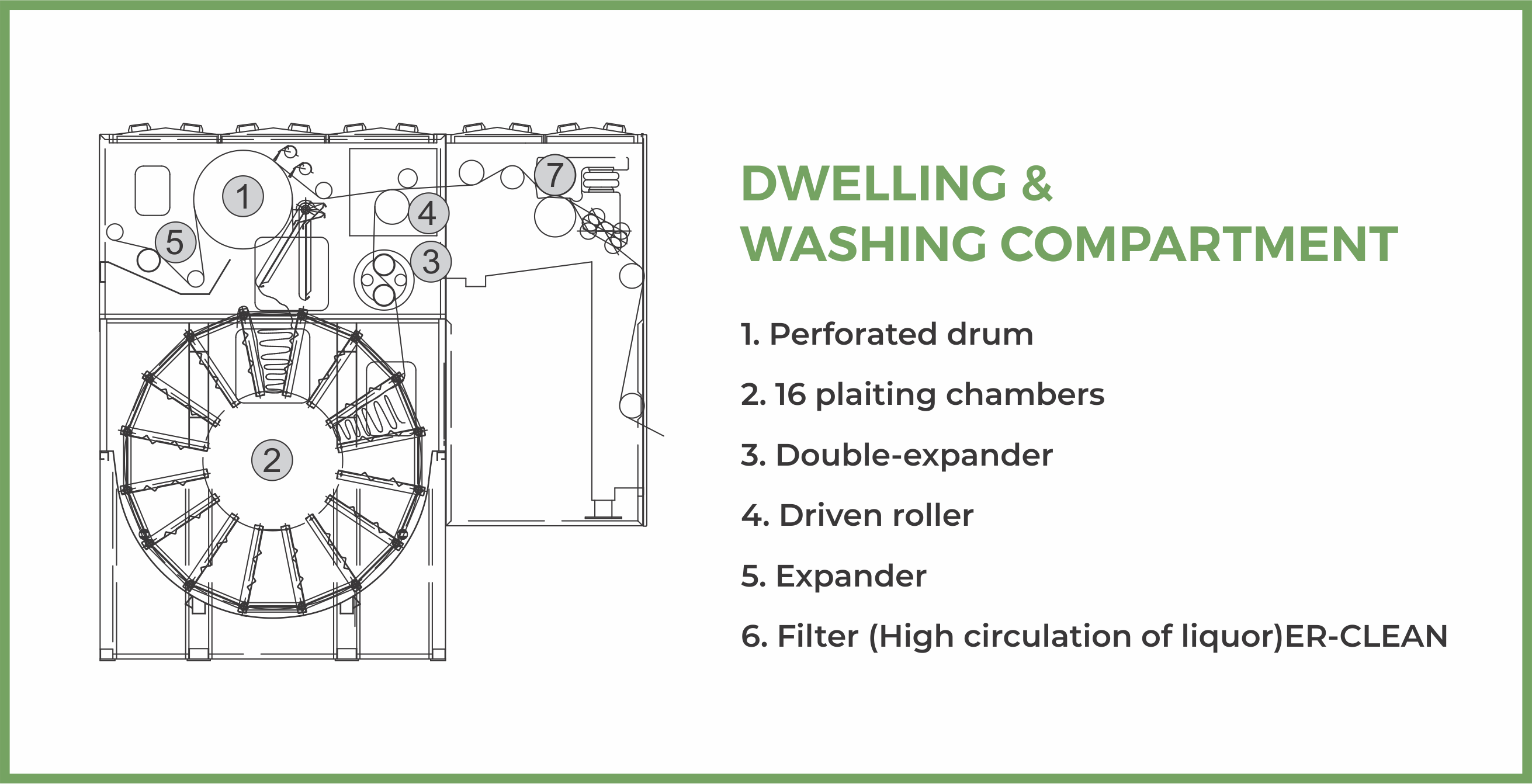

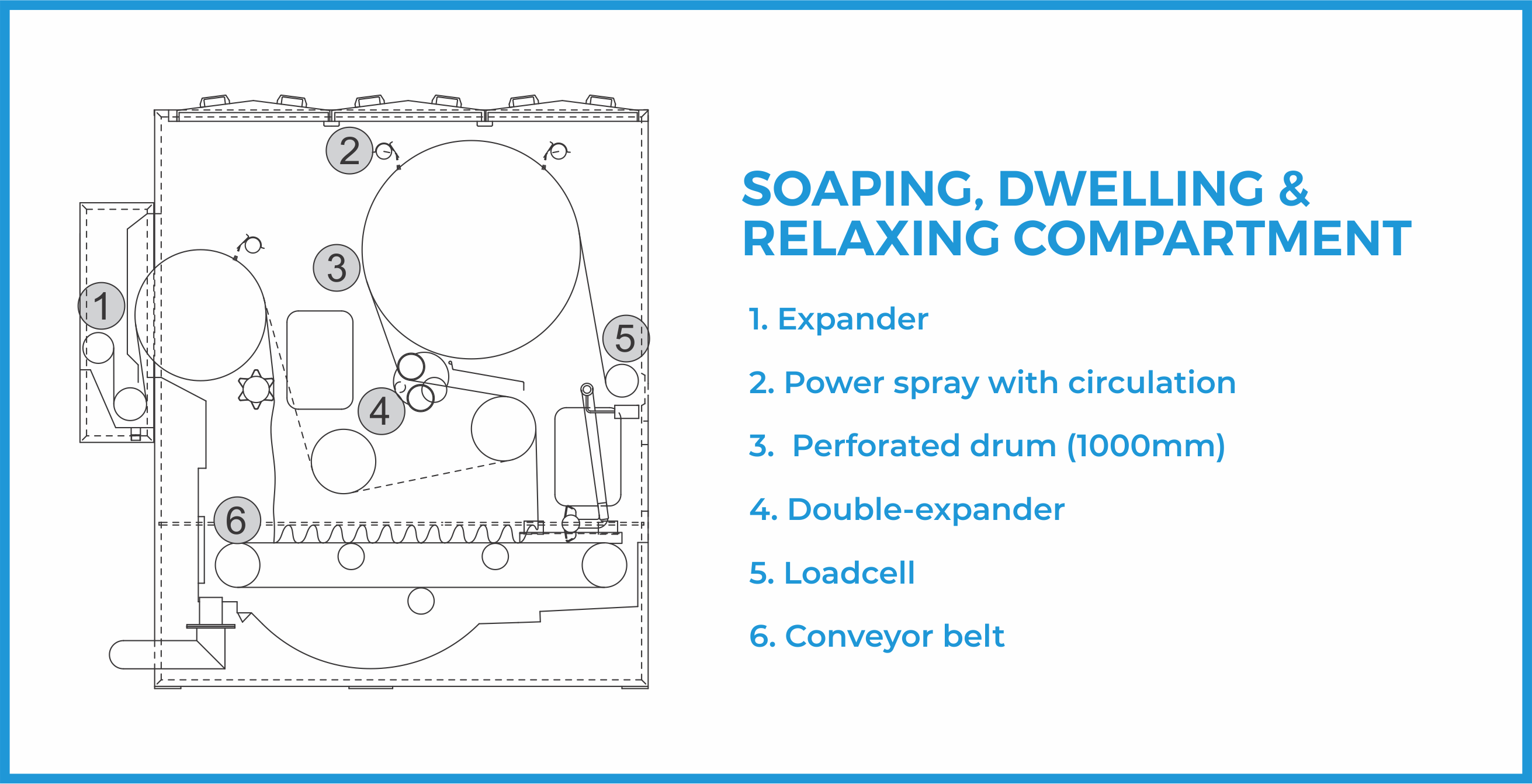

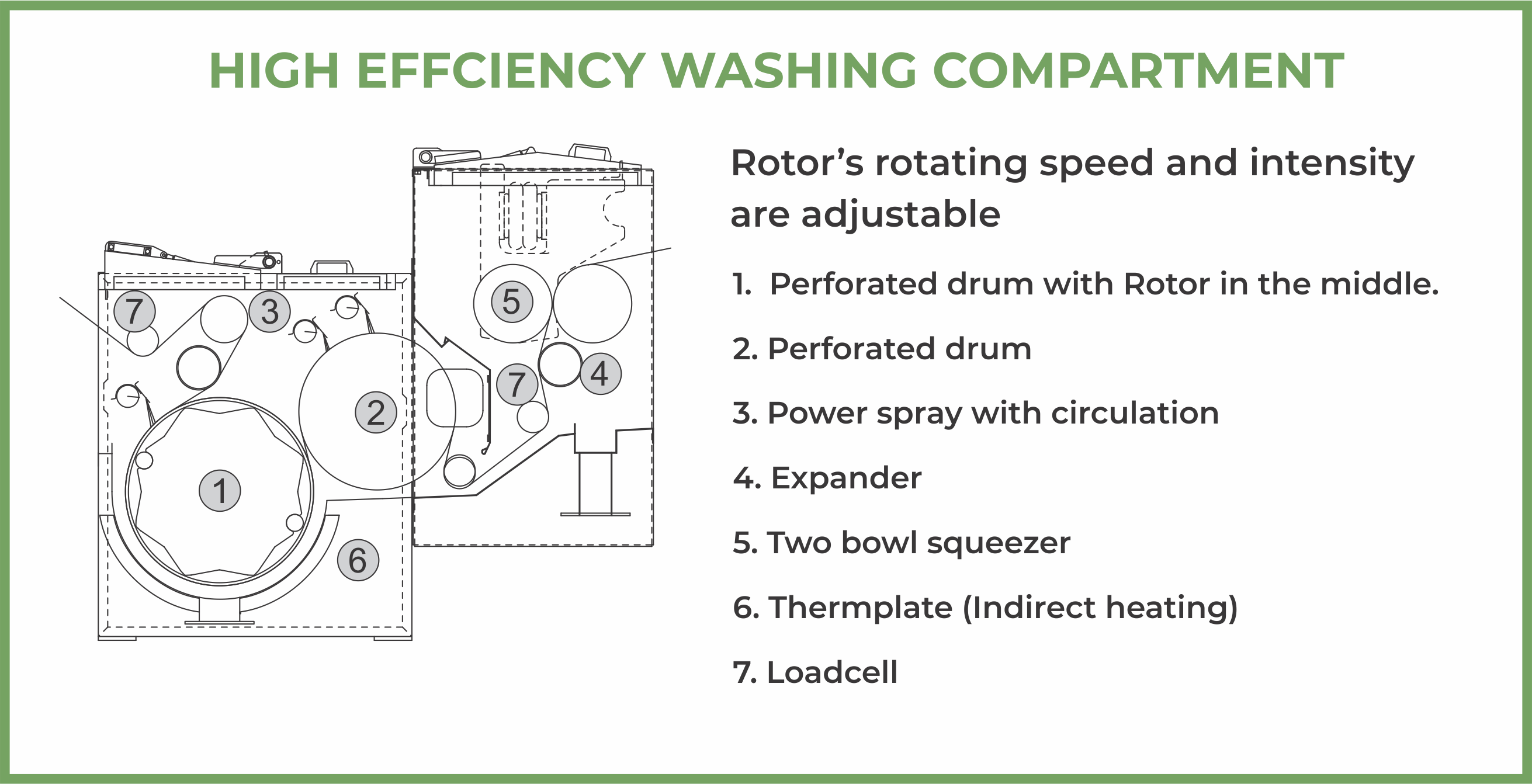

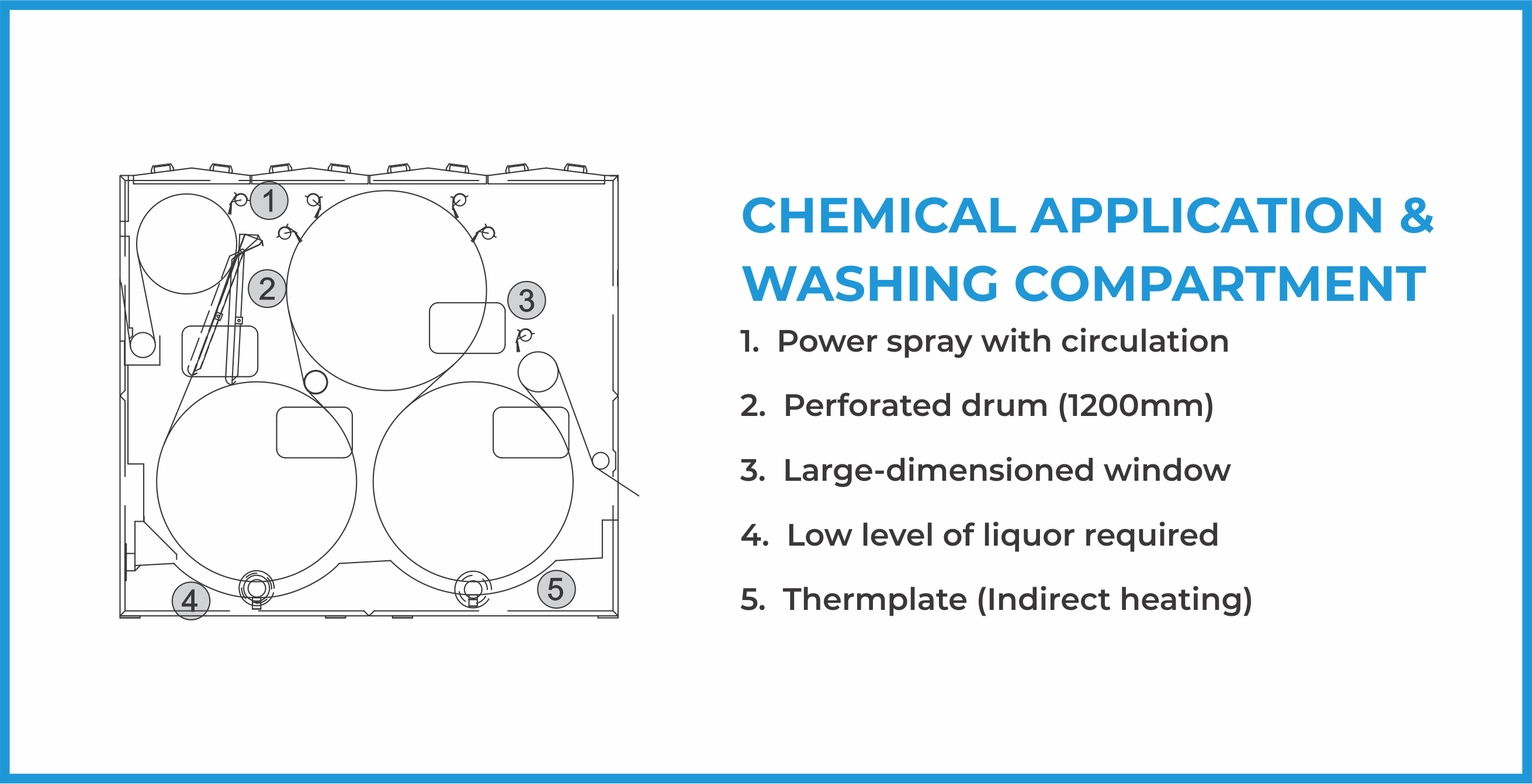

MACHINE IS SPECIALLY DESIGNED TO RUN KNITTED FABRICS SMOOTHLY. DE-CURLING UNIT TO PREVENT EDGE CURLING OF KNITTED FABRICS. SCROLL ROLLS TO PREVENT CREASE FORMATION LOAD CELLS FOR TENSION CONTROL IN KNITTED FABRICS ADVANCED IMPREGNATING SECTION WITH CAUSTIC DENSITY CONTROL HIGH EFFICIENCY CIRCULATION PUMPS FOR UNIFORM CHEMICAL APPLICATION ADVANCE CHAIN SECTION AND STABILIZING SECTION DRUM WASHERS AND SQUEEZERS SPECIALLY DESIGNED FOR KNITTED FABRICS.

MERCERISED KNITTED FABRICS ARE IN GREAT DEMAND FOR MAKING KNITWEAR/GARMENTS FOR NATIONAL & INTERNATIONAL HIGH-END FASHION BRANDS.

PRINCIPLE OF "FRONT AND BACK WASHING" THE WASHING LIQUID SEEPS INTO THE FABRIC AND LEAVES A "LM OF LIQUOR" ON THE FRONT AND BACK OF THE GARMENTS CONTAMINANTS ARE SWIFTLY REMOVED ON BOTH SIDES IN THIS WAY. COMPARED TO STRAIGHTFORWARD NET OR PERFORATED DRUM SYSTEMS, THE WASHING EFFECT IS INCREASED BY 40%.

‘FOURWENTS’ IS DISTINGUISHED BY ITS COMPREHENSIVE PROCESS KNOW-HOW IN BOTH APPLICATION CONSULTING AND PROJECT PLANNING AS WELL AS BY ITS CLOSE COMMUNICATION WITH CUSTOMERS THROUGHOUT THE ENTIRE LIFE CYCLE OF THE INSTALLED PLANTS. WITH ITS FOCUS ON ENGINEERING AND A HIGH STANDARD OF TECHNICAL COMPETENCE,

AS THE LEADER IN ITS LINE OF TECHNOLOGY, ‘FOURWENTS’ PROVIDES COMPETENT ADVICE AND SUPPLIES INNOVATIVE AND EFFECTIVE PRODUCT SOLUTIONS TO THE REQUIRED QUALITY STANDARD BY THE AGREED DEADLINE FOR A FAIR MARKET PRICE, BACKED BY RELIABLE, FIRST CLASS CUSTOMER SERVICE.