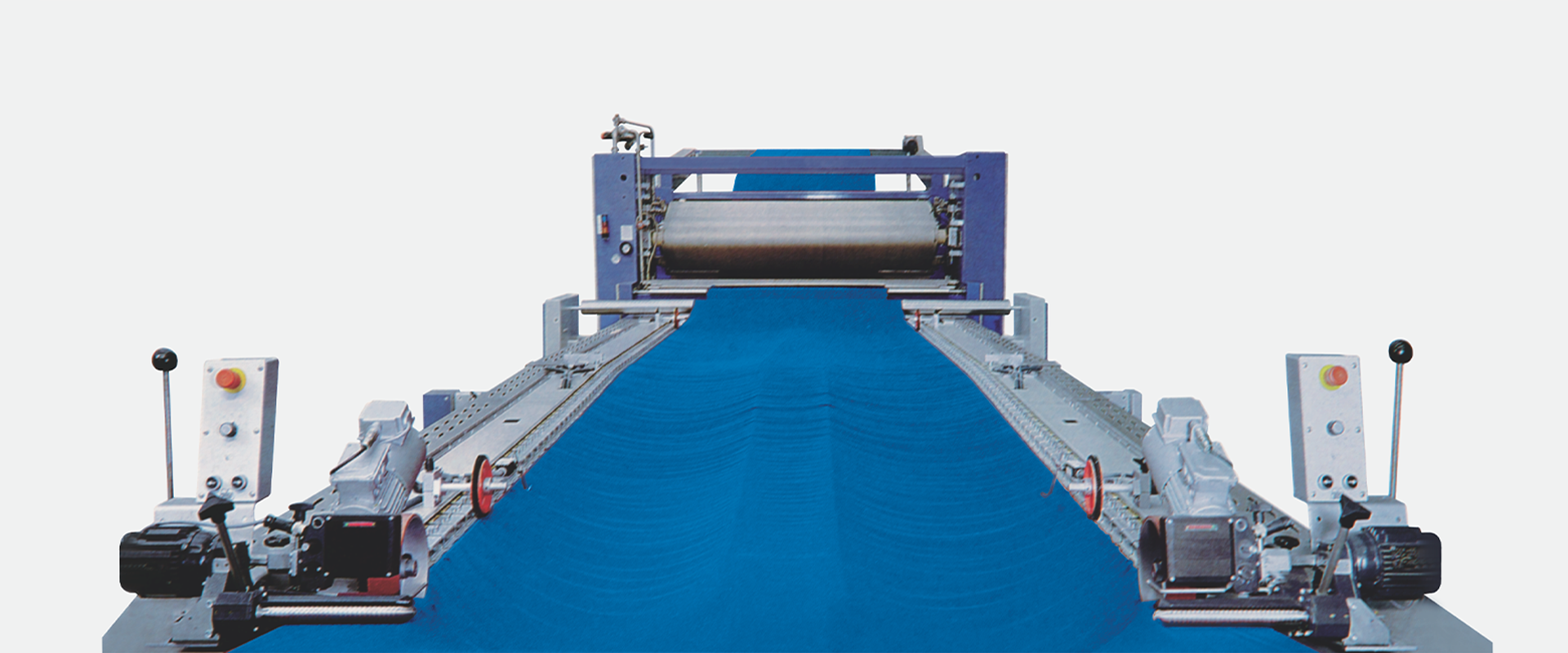

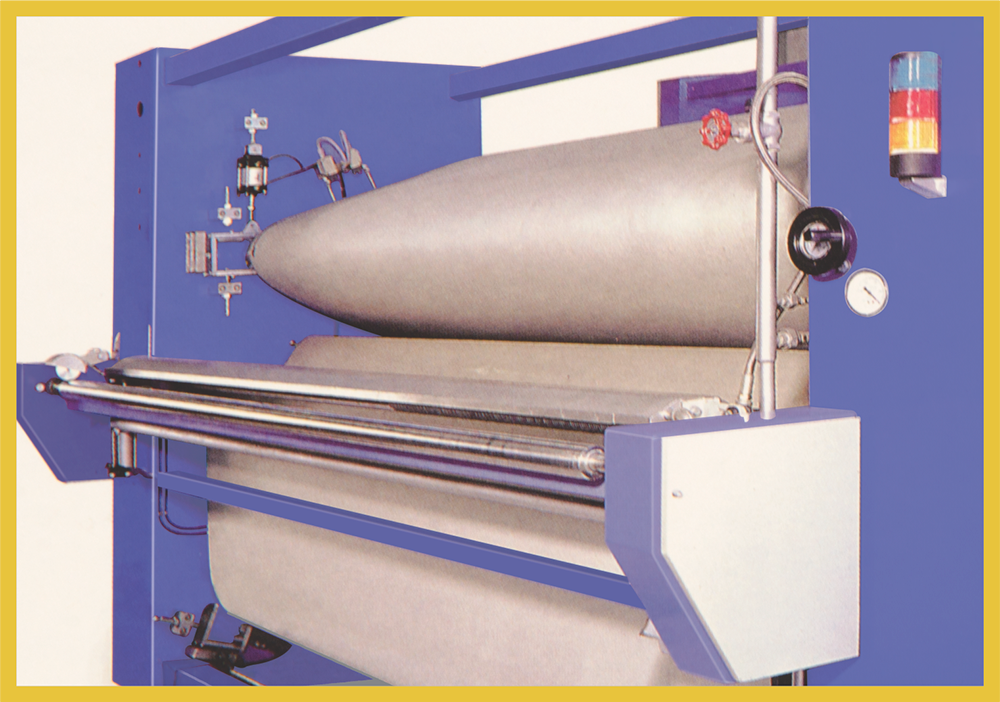

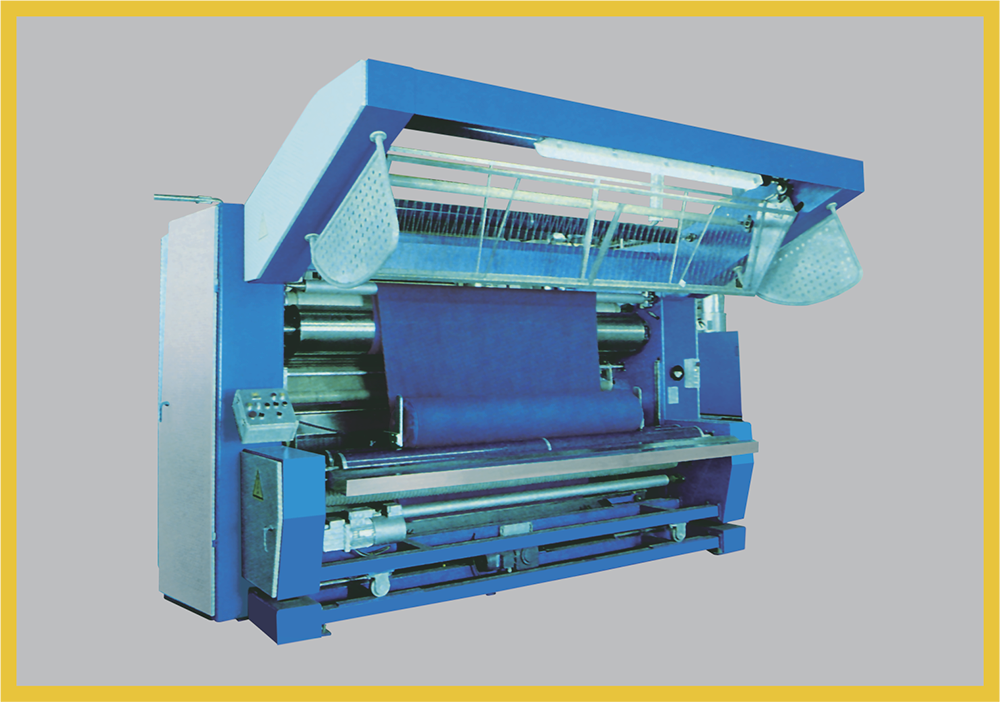

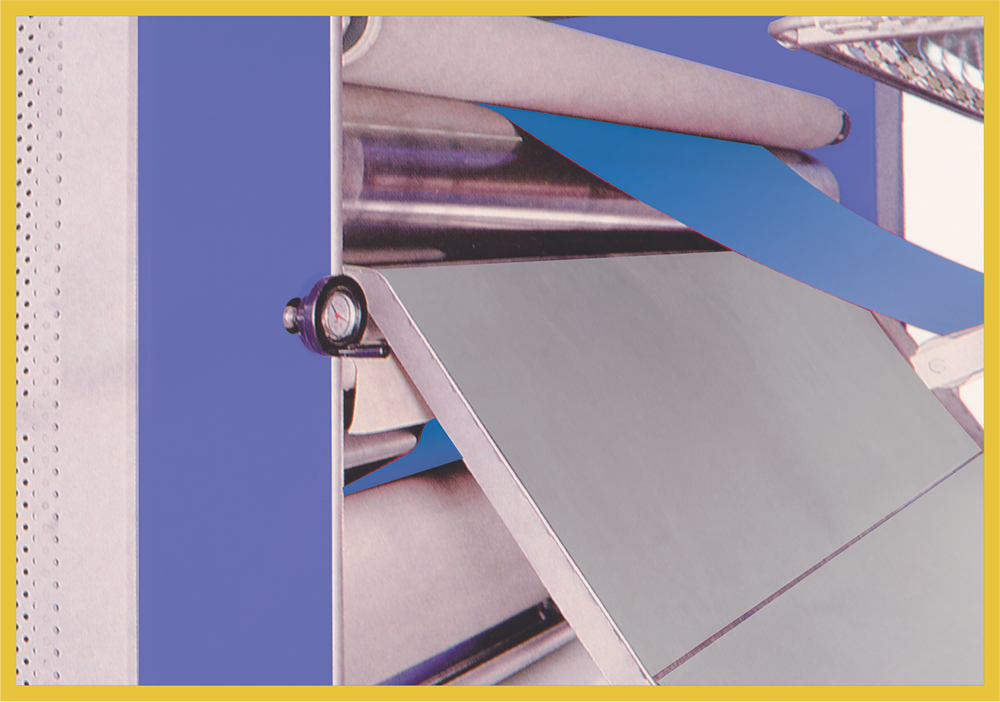

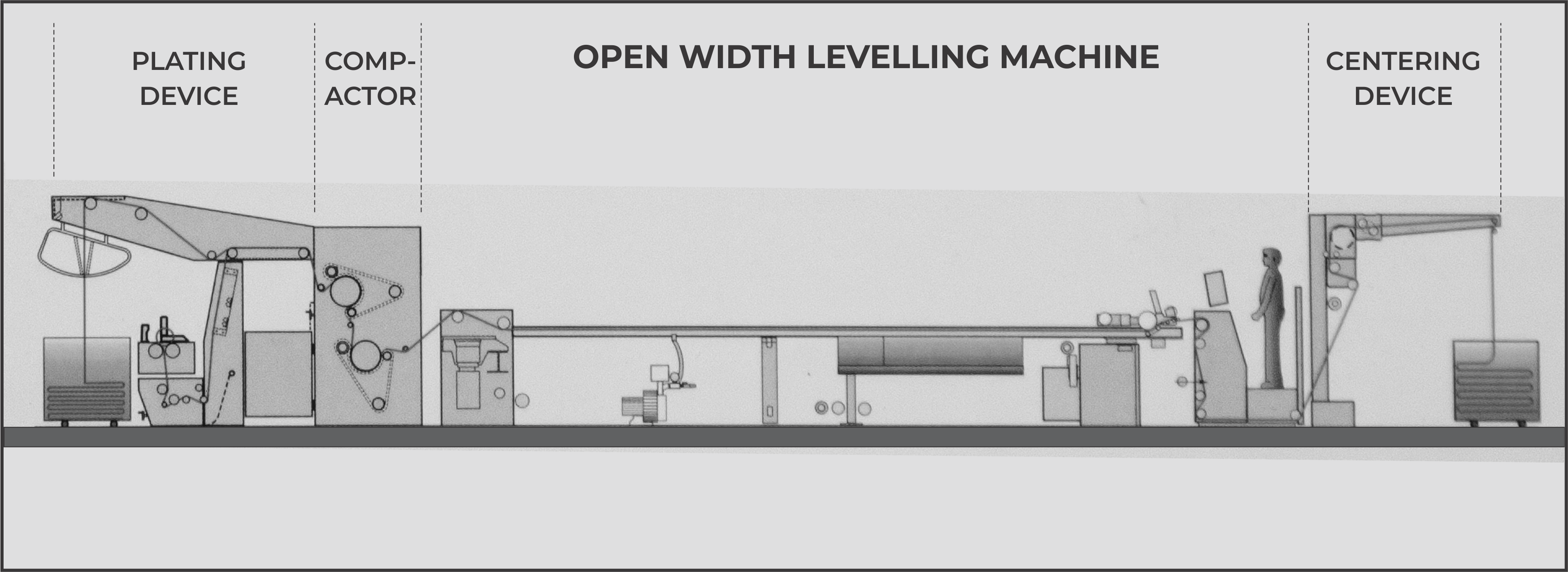

Fabric width dimensions are not always correct in both horizontal and vertical directions. A levelling machine stretches the fabric material horizontally. When a fabric is stretched, the vertical direction contracts, resulting in more material per unit length. Simultaneously, a large amount of steam is being blown under the fabric to help with stretching and vertical contraction. After being stretched and stabilised in width, the fabric exits the levelling machine and enters the compactor unit. When the fabric passes through the two compacting units, the vertical direction is corrected and stabilised.

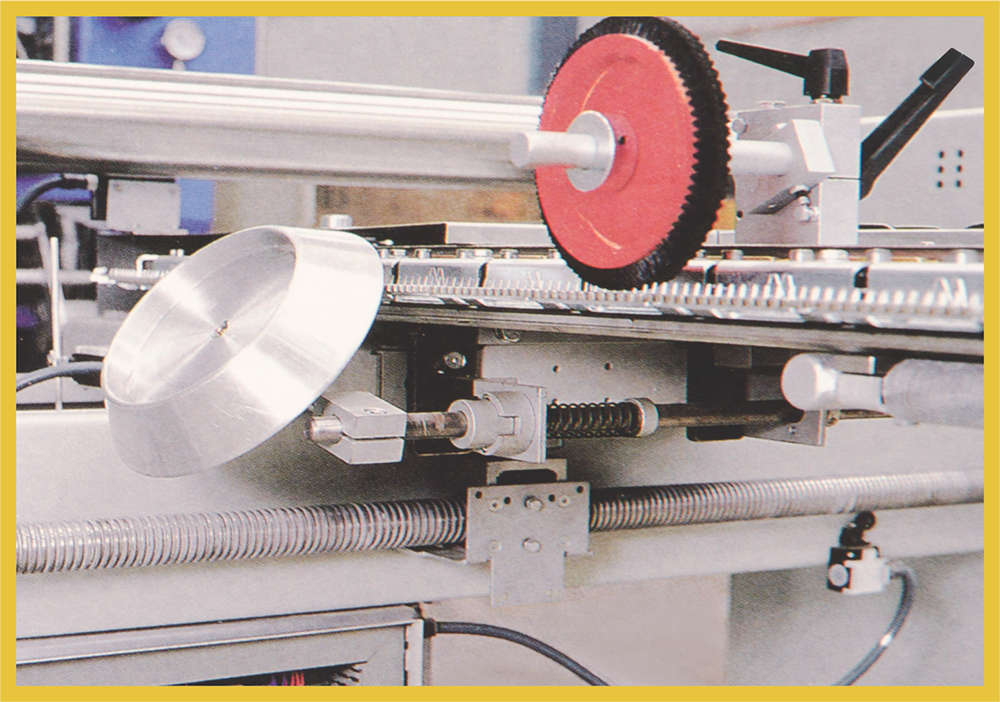

A precision control ensures that the fabric tension between the two compacting units is kept to a minimum. A plaiter is used to plait the fabric onto the loading cart when the finished fabric is not winded up. The levelling machine is a Fourwents product made with the best of the best Indian engineering and core technology of Europe.

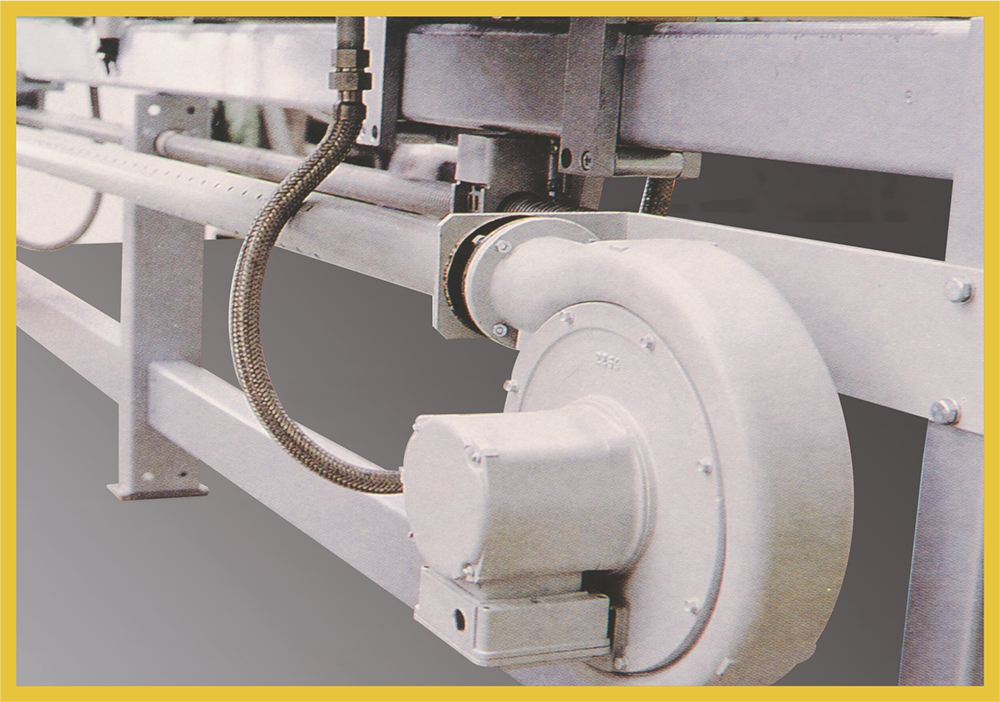

THE HORIZONTAL DIMENSION (WEFT DIRECTION), BUT NOT THE VERTICAL (WARP DIRECTION), IS STABILISED WHEN THE OPEN WIDTH FABRIC IS FINISHED. THE BEST MACHINE TO PROVIDE MORE THICKNESS AND DIMENSIONAL STABILITY IN THAT DIRECTION IS THE FCC-11 WITH TWO COMPACTING UNITS. THE FABRIC IS OPENED AND SPREAD BY SCROLL ROLLERS AT THE ENTRANCE. THE RUNNING FABRIC IS GUIDED TOWARD THE MACHINE'S CENTRE BY A CENTRING DEVICE. THE FABRIC IS THEN STEAMED AS IT PASSES OVER A STEAMING BOX AND ENTERS THE COMPACTING UNIT. TO AVOID CONDENSATION, ALL COMPONENTS THAT MIGHT COME INTO CONTACT WITH STEAM DURING THE PROCESS ARE HEATED. MINIMUM FABRIC TENSION BETWEEN THE TWO COMPACTING UNITS IS GUARANTEED BY PRECISE CONTROL. WHEN THE FINISHED FABRIC IS NOT WOUND UP, IT IS PLAITED ONTO THE LOADING CART USING A PLAITER.

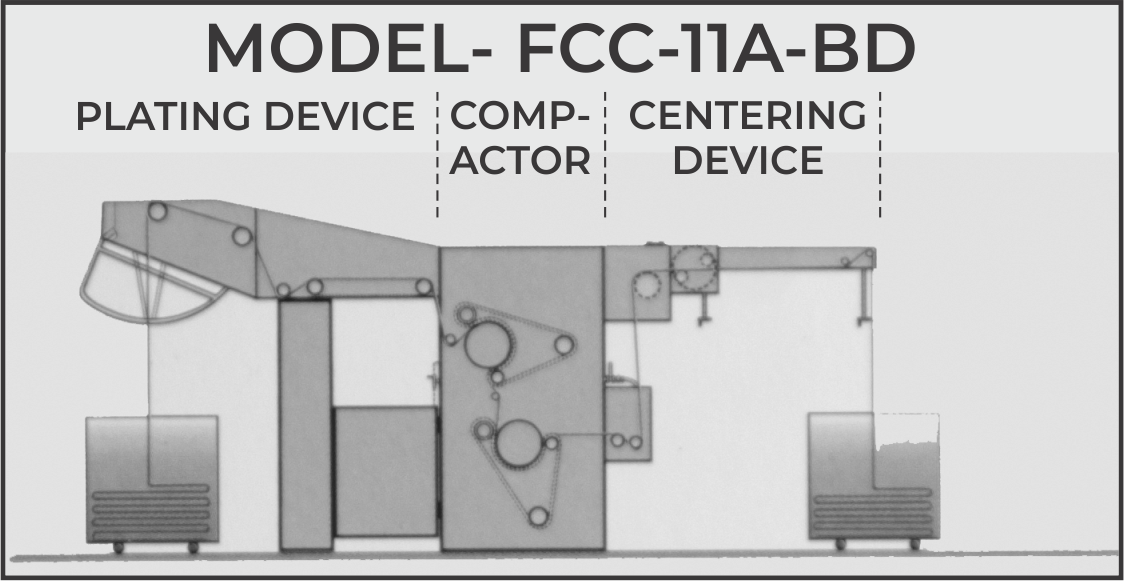

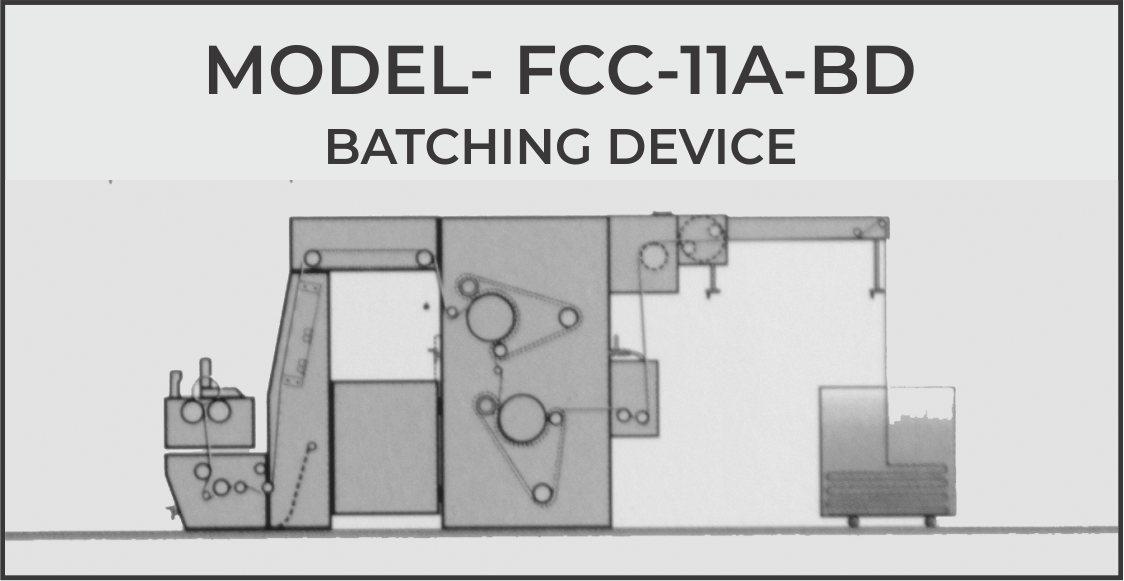

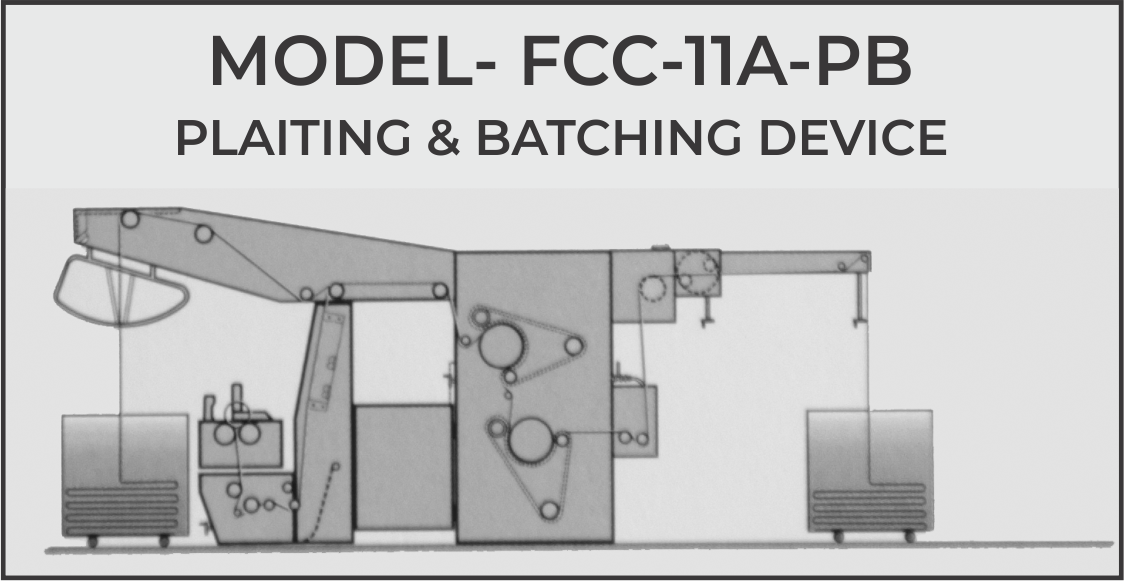

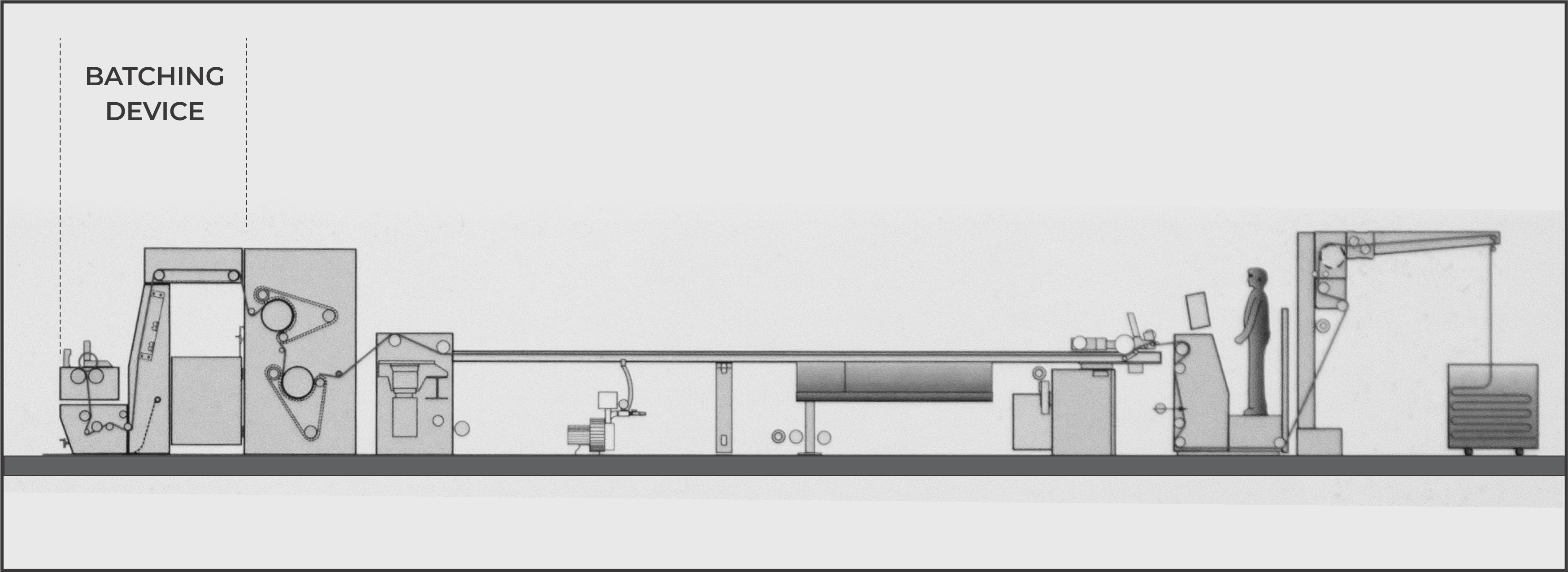

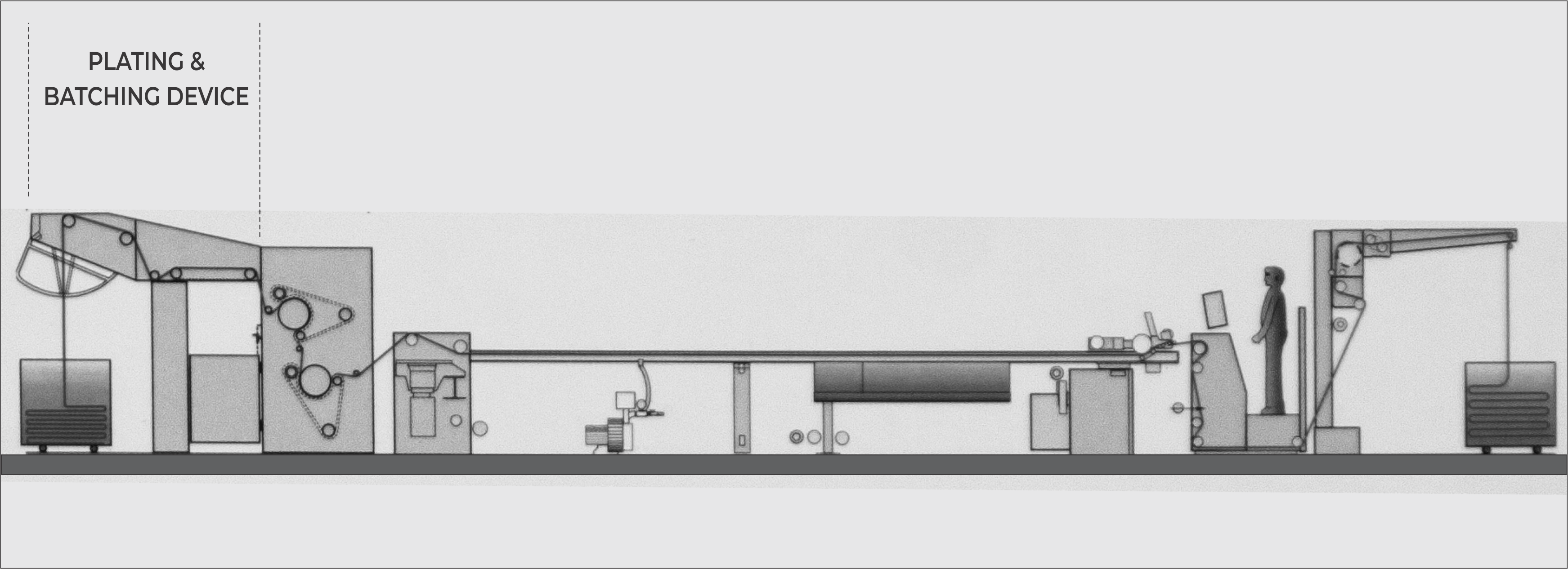

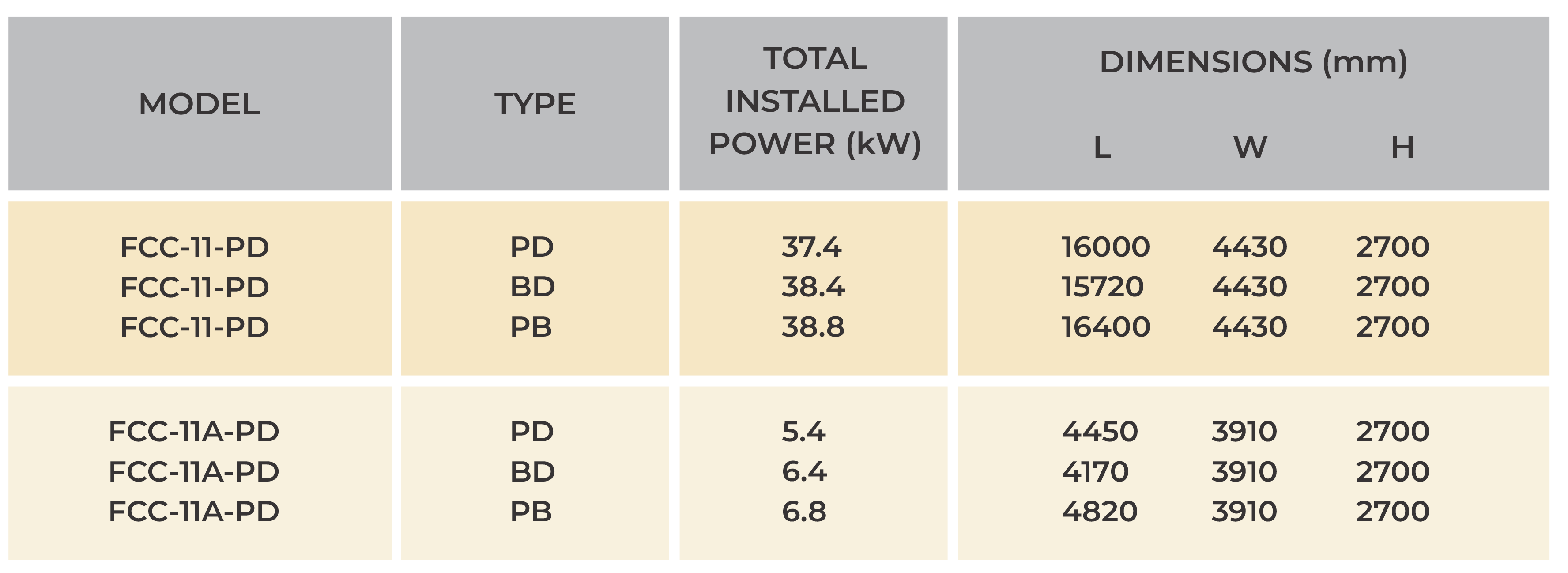

DESIGNATION:

TYPE: PD - ONLY WITH PLAITING DEVICE.

TYPE: BD - ONLY WITH BATCHING DEVICE.

TYPE: PB - ONLY WITH PLAITING & BATCHING DEVICE.