DUAL BENEFITS OF MERCERIZING OPEN WIDTH KNITTED AS WELL AS WOVEN FABRICS INCREASED ABSORBENCY OF KNITTED FABRICS IMPROVES LUSTRE OF THE KNITTED FABRICS INCREASED DIMENSION STABILITY OF THE KNITTED FABRICS INCREASED DYE ABILITY. 15-20% LESS DYE CONSUMPTION COMPARED TO UN-MERCERIZED KNITTED FABRICS EXCELLENT APPEARANCE POST DYEING AND PRINTING .

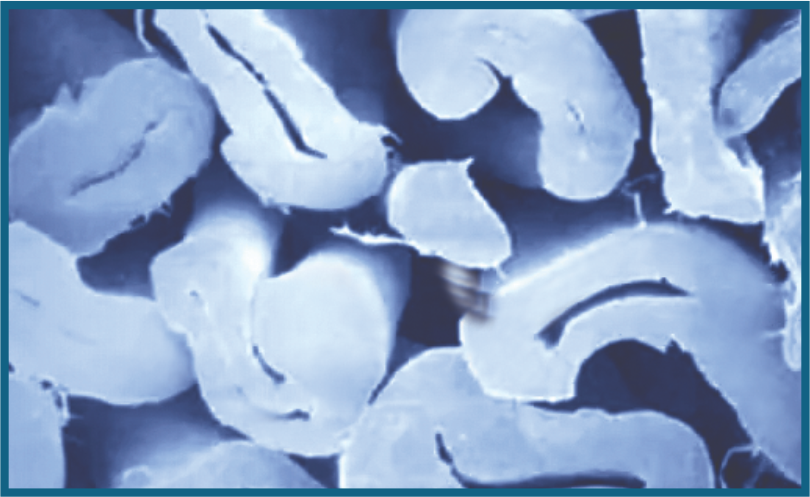

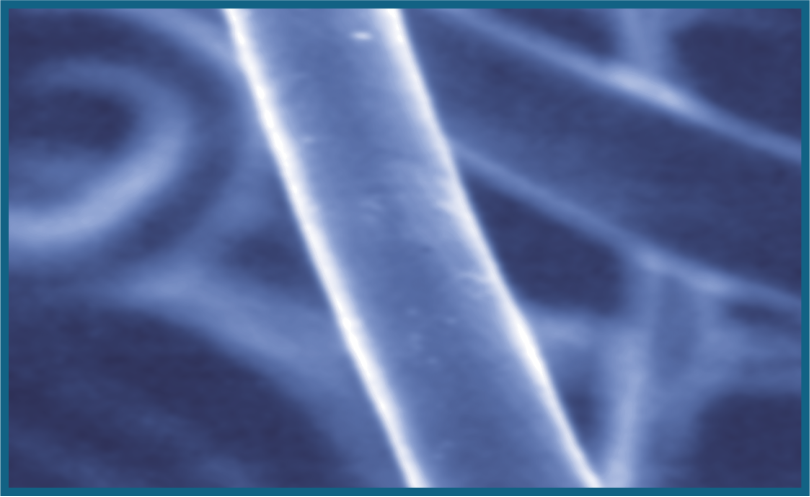

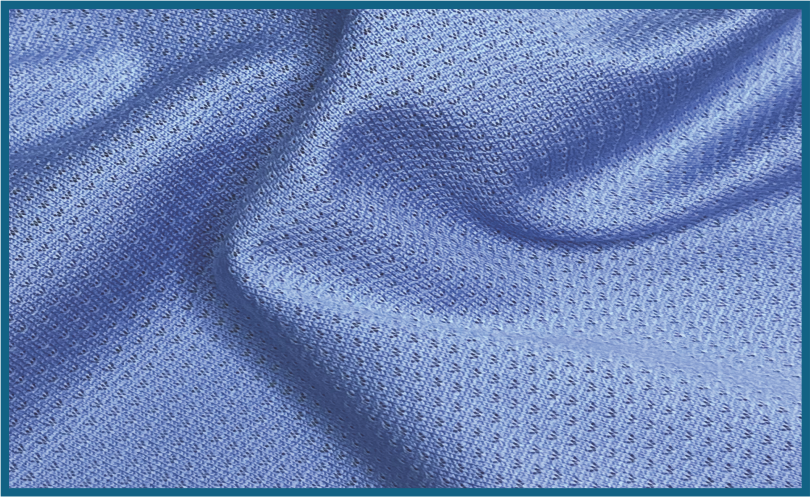

BEFORE MERCERIZE

(WRINKLED FIBER SURFACE)

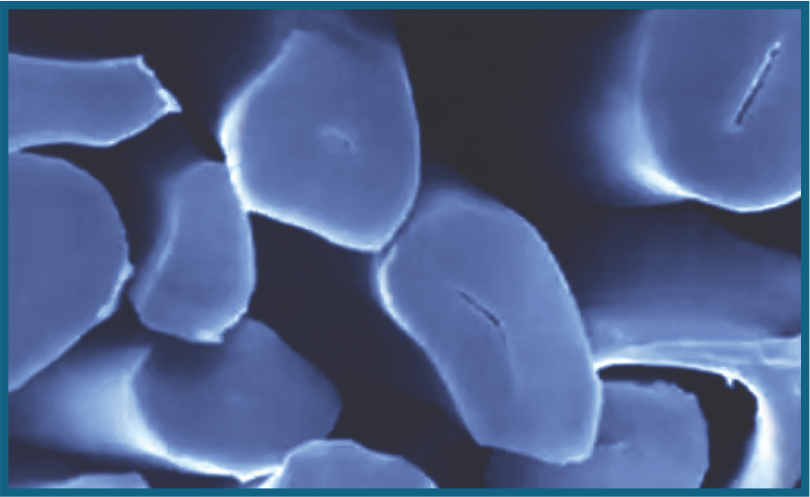

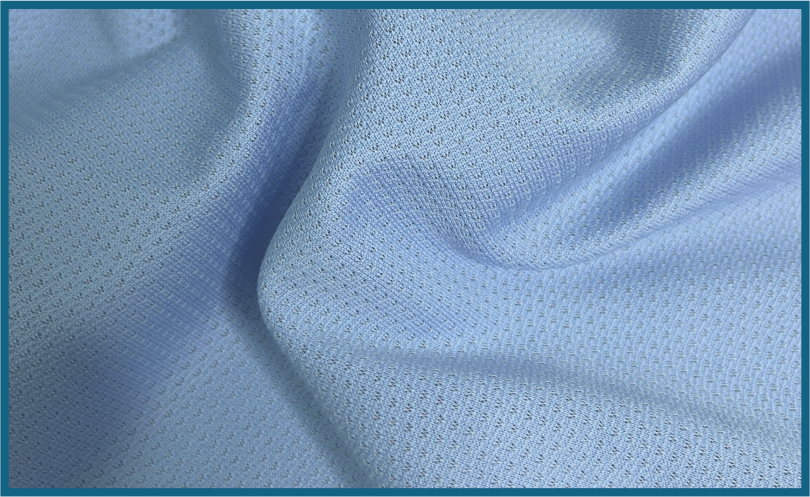

AFTER MERCERIZE

(SMOOTHER FIBER SURFACE)

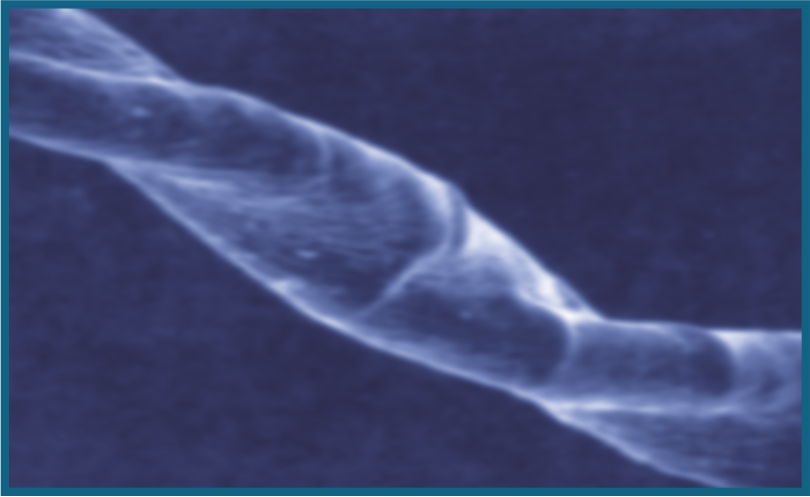

MERCERIZATION IS A PROCESS IN WHICH THE KNITTED AS WELL AS WOVEN FABRIC IS TREATED WITH CERTAIN PERCENTAGE OF LIQUID CAUSTIC TO INCREASE ITS STRENGTH, ANTI-SHRINK QUALITY, LUSTER AND INCREASED DYE AFFINITY.

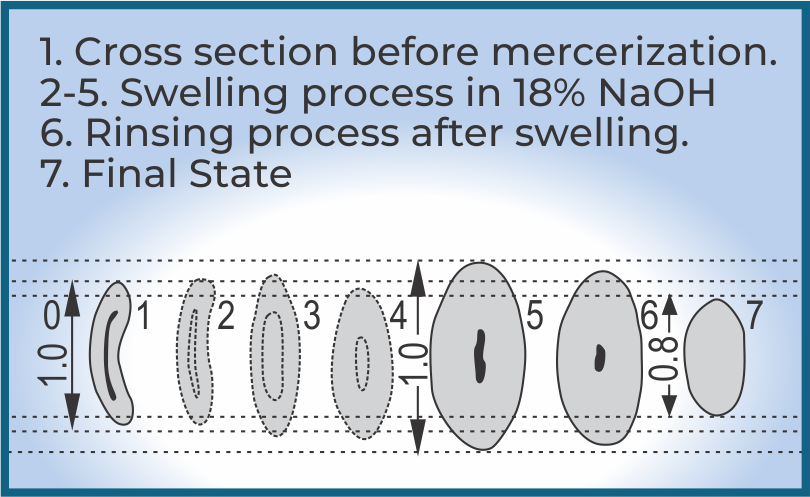

Changes of Cellulose Fibers Due to Mercerization process on Cotton Fabrics

Cotton Fiber Cross Section Before Mercerization

Cotton Fiber Cross Section After Mercerization

Before Mercerize (wrinkled Fiber Surface)

After Mercerize (smoother Fiber Surface)

In mercerization process cotton is Treated with Alkaline Solution

By merserization process,

More absorbed dye & gives bright colors

In mercerization process Improves strength

Caustic Soda Process In Mercerization

Shrinkage resistance

Soft, Shine & Silky Feel

WHILE HANDLING FABRICS, YOU MAY HAVE NOTICED THAT SOME HAVE A BRIGHT LUSTER AND ARE ALSO QUITE SOFT, WHILE OTHERS HAVE VERY DULL COLORS. THIS RELATES TO THE MERCERIZATION PROCESS. IN THIS PROCESS, COTTON IS TREATED WITH AN ALKALINE SOLUTION TO IMPROVE COTTON FABRIC LUSTER, DYE ABSORPTION, AND STRENGTH. CAUSTIC SODA CAUSES SIGNIFICANT SWELLING OF COTTON FIBER, INCREASING THE CROSS-SECTION OF COTTON FIBER BY APPROX. 40 TO 50% WITH A SIGNIFICANT INCREASE IN LENGTH (ABOUT 1 TO 2%). COTTON FIBER SWELLING TRANSFORMS ITS CROSS-SECTION FROM A KIDNEY SHAPE TO A CIRCULAR SHAPE, INCREASING LUSTER.

WHEN COTTON FIBER IS MERCERIZED, ITS STRENGTH IS INCREASED BY APPROX. 10 - 50% BECAUSE CIRCULAR SHAPES REQUIRE MORE FORCE TO BREAK THAN KIDNEY SHAPES. ALSO, DUE TO PHYSIO-CHEMICAL CHANGES, THE DYE AFFINITY PROPERTY OF COTTON INCREASES, AND THE FABRIC TENDS TO ABSORB MORE DYE AND IMPART BRIGHT COLOR WITH FEWER CHANCES OF COLOR FADING. TO IMPROVE SHINE, GLOSS, AND SOFTNESS,

AS WELL AS SHRINKAGE RESISTANCE, MOISTURE RETENTION, AND DYE ABSORPTION, TO IMPROVE STRENGTH AND ELONGATION, AS WELL AS TO INCREASE THE SMOOTHNESS OF THE CLOTH, MERCERIZATION IS PERFORMED.

THE CONCENTRATION OF CAUSTIC SODA IN SCOURING IS AROUND 5 TO 10%, WHEREAS THE CONCENTRATION IN MERCERIZATION IS PERHAPS UP TO 20 TO 25%.

FABRICS MADE ENTIRELY OF SYNTHETIC MATERIALS, SUCH AS POLYESTER AND NYLON, ARE NOT MERCERIZED.